In today’s industrial, commercial, and building sectors, choosing the right insulation is no longer just about temperature control—it’s about safety, compliance, energy efficiency, and long-term performance. Whether you’re dealing with building envelopes, mechanical systems, or industrial pipe insulation types, verifying that insulation materials meet CAN/ULC and ASTM standards is essential. Doing so protects your project, ensures regulatory acceptance, and guarantees reliable thermal performance in real working environments.

This guide walks you step-by-step through what these standards mean, how to verify compliance, what technical documents to check, and how to confidently select qualified pipe insulation material backed by standardized testing and certification.

Understanding CAN/ULC Standards for Insulation

What CAN/ULC Standards Represent

CAN/ULC standards ensure insulation materials used in Canada are reliable, safe, and suitable for local climate and industrial conditions.

- Safety & Fire Performance: Focuses heavily on flame spread, smoke development, and fire resistance to protect facilities and workers.

- Thermal Effectiveness: Ensures insulation delivers consistent heat resistance without unexpected loss in real applications.

- Environmental Suitability: Validates materials for moisture resistance, condensation control, and durability in cold or humid environments.

- Regulatory Approval: Required for compliance with Canadian Building Codes and many industrial engineering specifications.

Key Performance Areas Evaluated Under CAN/ULC

These standards do more than add a certification label—they prove reliability.

- Thermal Resistance Stability: Ensures insulation maintains its insulating ability over time.

- Flame Spread Index: Prevents insulation from becoming a fire hazard.

- Smoke Development Rating: Reduces risk in enclosed mechanical rooms or industrial environments.

- Water Absorption Control: Protects against mold, corrosion under insulation, and insulation failure.

Where CAN/ULC Compliance is Most Critical

Not all projects carry the same risk level, but these applications require strict compliance:

- Industrial Piping & Mechanical Systems

- Commercial and Industrial Buildings

- Cold Storage & Refrigeration

- HVAC ducting and mechanical insulation

- Energy facilities and chemical plants

Understanding ASTM Standards for Insulation

What ASTM Standards Mean in the Industry

ASTM standards provide internationally recognized benchmarks that unify testing procedures and product expectations.

- Global Acceptance: Used worldwide in engineering, construction, and industrial sectors.

- Reliable Comparison Basis: Allows engineers to compare insulation materials fairly.

- Performance Consistency: Ensures every batch manufactured meets the same standard.

- Project Documentation Support: Used in specifications, tendering, and inspections.

Core Performance Aspects ASTM Evaluates

ASTM focuses on measurable, scientifically tested performance:

- Thermal Conductivity & R-Value Stability

- Mechanical Strength & Compression Resistance

- Water Vapor Permeability & Moisture Performance

- Temperature Range & Heat Exposure Performance

- Material Density & Structural Integrity

Why ASTM Compliance Matters to Engineers & Contractors

Choosing ASTM-certified insulation eliminates uncertainty:

- Guarantees predictable performance

- Reduces safety risk and liability

- Simplifies approval during inspection

- Enhances long-term cost efficiency

Practical Steps to Verify CAN/ULC & ASTM Compliance

| Step | What to Do | Check Items | Why It Matters |

| Step 1 | Check Labels & Markings | CAN/ULC code, ASTM reference, certification body, approval mark | Confirms the material is officially tested and recognized |

| Step 2 | Request Documentation | Compliance certificate, lab test reports, PDS, SDS, fire & thermal reports | Provides proof of safety and performance |

| Step 3 | Match to Applications | Pipe insulation, HVAC, building, industrial, refrigeration | Ensures standards suit the intended use |

| Step 4 | Verify Technical Specs | Thickness, size, temperature range, environment suitability, size chart | Prevents performance loss due to wrong selection |

| Step 5 | Choose Reliable Manufacturer | Certification history, quality control, support, transparency | Ensures long-term reliability and compliance |

Step 1: Check Certification Labels & Markings

A compliant insulation product should always clearly show:

- CAN/ULC standard code reference

- ASTM standard compliance reference

- Certification body or testing laboratory

- Approval/logotype mark

If these are missing, request verification before using the material.

Step 2: Request Official Documentation

Reliable insulation Material Manufacturer partners always provide proper documentation.

- Certificate of Compliance

- Third-party lab test reports

- Product Data Sheet (PDS)

- Safety Data Sheet (SDS)

- Fire resistance test certificate

- Thermal performance reports

If a supplier cannot provide these, compliance is questionable.

Step 3: Match Standards to Correct Applications

Different insulation applications follow different standards:

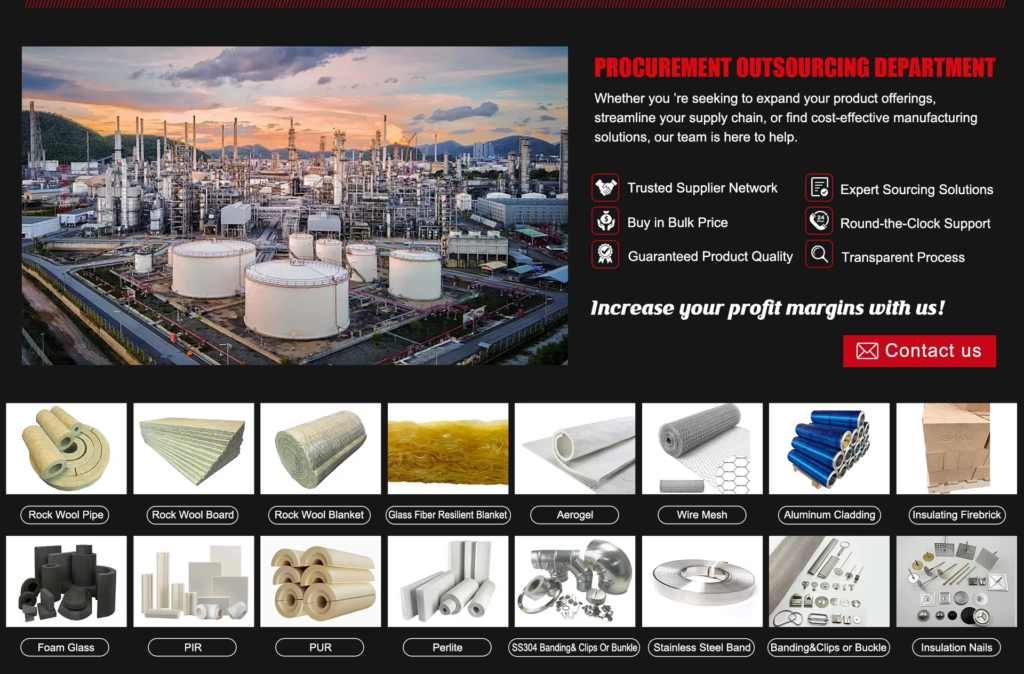

- Mechanical & pipe insulation material

- Industrial systems & chemical piping

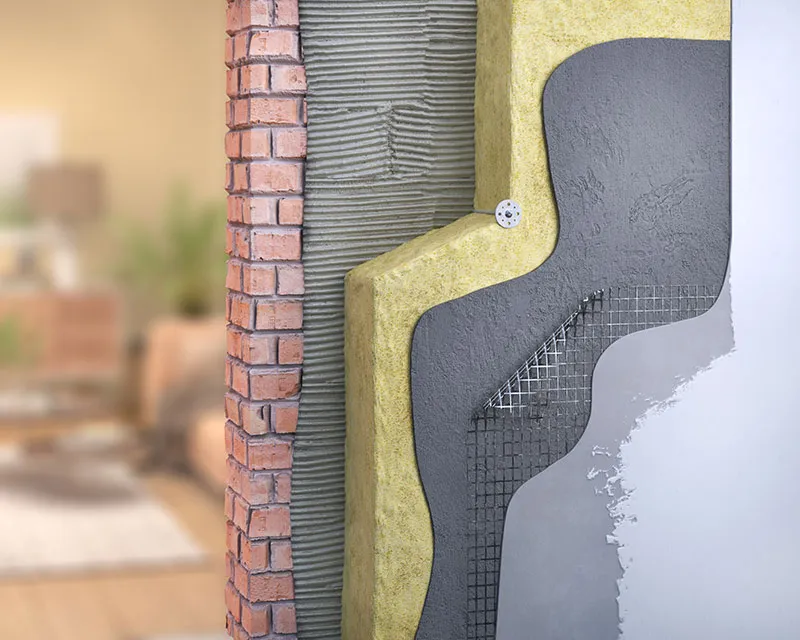

- Building wall insulation

- HVAC systems

- Cryogenic & refrigeration insulation

Ensuring the right standard applies prevents failure in demanding environments.

Step 4: Verify Technical Specifications & Sizing

Certification is only half the job—correct selection is equally important.

Use a pipe insulation size chart and verify:

- Correct thickness for required temperature range

- Diameter compatibility for piping sizes

- Thermal performance level

- Environmental and operating condition suitability

- Installation method requirements

Wrong sizing can reduce efficiency, even if the material itself is certified.

Step 5: Choose Trusted & Experienced Manufacturers

Partnering with a professional insulation Material Manufacturer ensures:

- Certified production processes

- Documented traceability

- Stable product quality

- Technical support availability

- Compliance assurance

Frequently Asked Questions

How to Tell If a Material Is a Good Insulator?

A strong insulating material typically shows:

- High R-value → better heat resistance

- Low thermal conductivity

- Moisture resistance

- Stable performance under temperature variation

- Verified CAN/ULC or ASTM certification

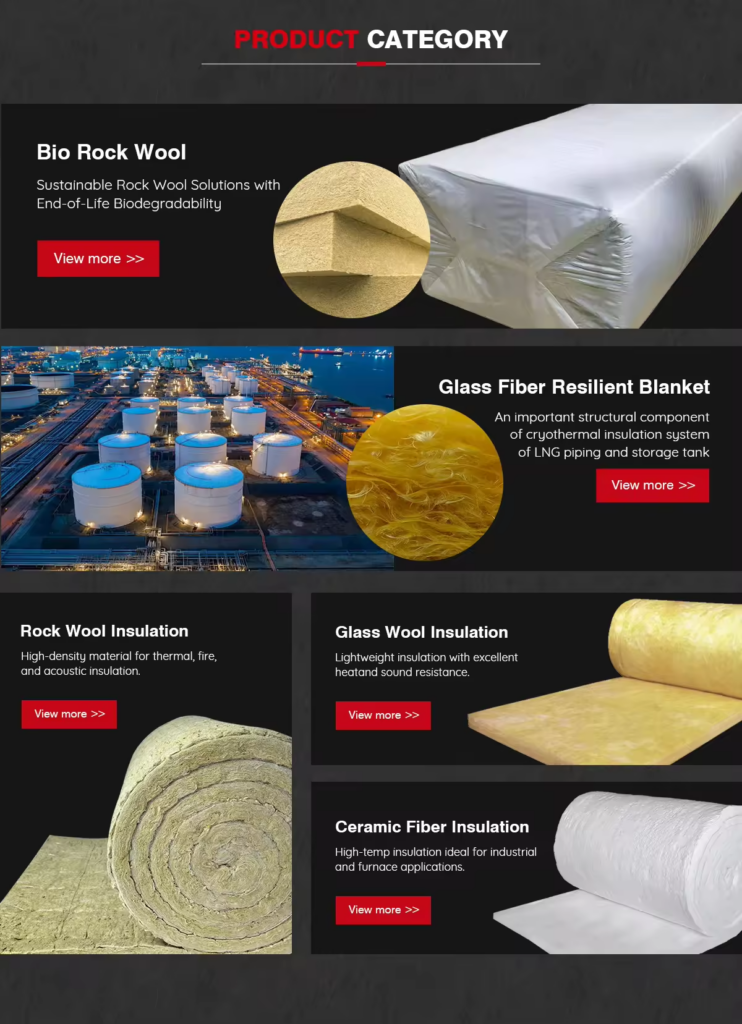

Materials commonly considered excellent include elastomeric foam, mineral wool, fiberglass, polyurethane foam, and aerogel—especially effective for industrial pipe insulation types.

What Readings Are Acceptable for Insulation Tests?

Acceptable readings depend on application, but typically require:

- R-value meeting minimum regulatory requirement

- Thermal conductivity matching engineering standards

- Fire test values passing CAN/ULC limits

- Moisture absorption below defined thresholds

- Temperature endurance suitable for the system

Industrial engineers compare test data with project specifications to confirm suitability.

What Is a Standardized Rating for Insulating Materials?

Insulation materials are commonly evaluated using:

- R-value (thermal resistance rating)

- K-value (thermal conductivity)

- Fire safety ratings

- CAN/ULC and ASTM certification references

These standardized indicators make it easy to compare performance and validate compliance.

Conclusion: Smart Verification Leads to Safer, More Efficient Projects

Ensuring insulation meets CAN/ULC and ASTM standards is not a procedural step—it’s a critical investment in safety, efficiency, and long-term operation stability. Whether you are selecting building insulation or evaluating industrial pipe insulation types, checking certifications, reviewing test documentation, understanding performance ratings, and using a pipe insulation size chart ensures your system performs exactly as intended.

Always work with a trusted insulation Material Manufacturer that provides transparency, professional support, and officially certified products. With the right verification approach, you can confidently build safer, more energy-efficient, and fully compliant insulation systems.