Think of insulation like a protective layer for your building. Rigid foam acts like a plastic raincoat that traps moisture, while الصوف الصخري functions like a breathable, fireproof stone sweater.

This guide compares their critical metrics, analyzing long-term قيمة R stability, fire safety codes, and total project costs to help you select the right material for your exterior walls.

الصوف الصخري مقابل. Rigid Foam (XPS/EPS)

In simple terms: Rock wool is like a stone shield that handles fire and heat without changing shape, while plastic foams are like rigid coolers that insulate well initially but can shrink or burn over time.

Material Profiles: Stone Wool vs. Extruded (XPS) and Expanded (EPS) Polystyrene

Stone wool uses spun rock fibers to make solid boards. These boards let moisture pass through and will not catch fire. You can think of it like cotton candy made out of stone.

XPS forms a hard plastic foam with a smooth outer skin. It keeps water out very well and acts like a stiff board. Builders often use it for walls that go underground because it is hard to crush.

EPS consists of small plastic beads melted together into a block. It is lightweight and costs less than the other options. This is the same white foam material you see used to package new electronics.

Critical Metrics Snapshot: قيمة R, Fire Class & Stability Data

XPS takes the lead for holding in heat when it is new. It offers an insulation value of roughly R-5.0 per inch. Rock wool follows closely behind with slightly lower numbers.

Rock wool earns the top rating for fire safety. It is rated Euroclass A1 because it simply does not burn. Both foam types are typically rated Class E and act as fuel for a fire.

Rock wool keeps its exact shape even when temperatures change drastically. Foams face the risk of shrinking or warping as they age. This movement can create gaps that let heat escape from the building.

الصوف الصخري مقابل. Rigid Foam on Thermal Performance & R-Values

In simple terms: Rigid foam offers more insulation per inch at the start, but rock wool keeps its performance forever while foam slowly loses its insulating power as it ages.

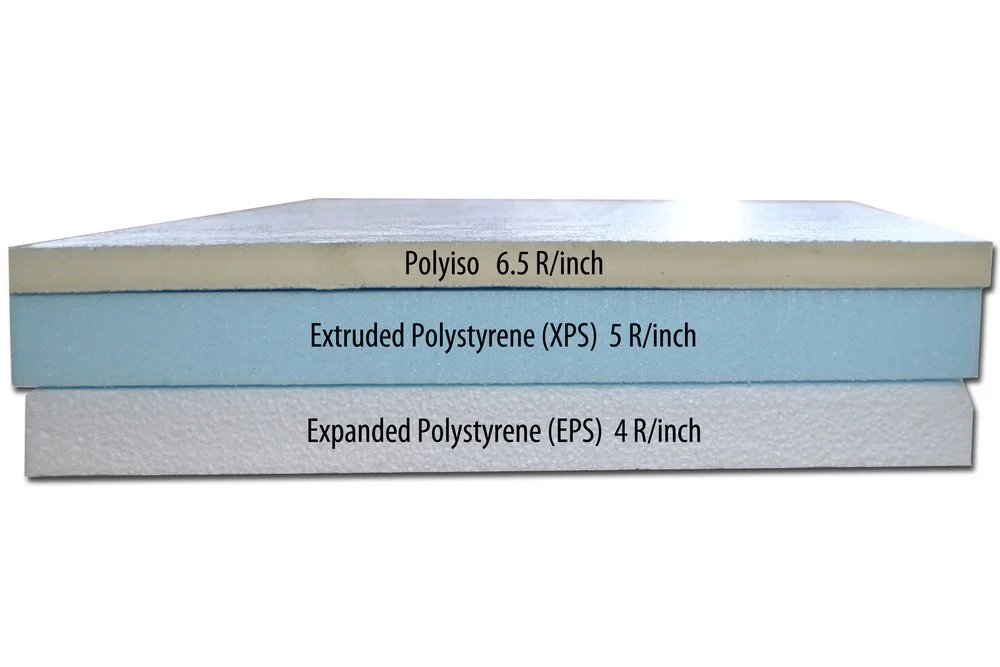

Initial R-Value Comparison: Thickness Efficiency and Rated Performance

Rigid foam is often the winner if you have very limited space to build. It packs a lot of insulation into a thin board. This makes it a common choice when walls need to stay slim.

Polyiso foam typically provides the highest rating, offering about R-5.0 to R-6.0 for every inch of thickness. Other foams like XPS and EPS fall slightly lower but still generally offer higher numbers per inch than mineral wool.

Rock wool is a bit bulkier by comparison. It generally provides R-3.0 to R-4.2 per inch. You would need a slightly thicker layer of rock wool to match the initial warmth rating of a high-performance foam board.

Long-Term Thermal Stability: R-Value Drift and Dimensional Consistency

This is where the engineering reality changes significantly. Many rigid foams experience a phenomenon called thermal drift. This means their ability to insulate decreases as the building gets older.

Think of rigid foam like a balloon filled with a special, heavy gas. Over time, that special gas leaks out and is replaced by normal air. As this happens, the material loses some of its insulating power.

Rock wool does not drift because it relies on trapped air within stone fibers rather than gas. It keeps its labeled performance level indefinitely without aging effects. It is a stable investment for a building meant to last decades.

Rock wool also resists changing shape when the temperature swings. Foam can expand and contract significantly, which may create gaps in your insulation layer. Rock wool stays roughly ten times more stable dimensionally, preventing those energy-leaking gaps.

الصوف الصخري مقابل. Rigid Foam on Moisture Resistance & Exterior Wall Protection

In simple terms: Think of rock wool like a breathable sports jersey that lets moisture vapor escape, while rigid foam acts more like a plastic raincoat that traps moisture inside the wall, which can lead to hidden rot.

Vapor Permeability and Drying Dynamics

Rock wool boards are naturally breathable materials. At a standard 2-inch thickness, they maintain a vapor permeability rating of about 30 perms. This allows moisture vapor to pass freely through the insulation so the building can dry out naturally.

Rigid foam boards like XPS or Polyiso function very differently. They typically act as vapor retarders with low permeability. If moisture gets into the wall cavity from the inside, the foam can trap it there like a barrier.

Trapped moisture is a primary cause of mold and rot in cold climates. Using permeable stone wool prevents the dangerous double vapor barrier effect. This ensures that if the interior vapor barrier ever leaks, the wall assembly can still dry to the outside.

Bulk Water Management and Dimensional Stability

Building materials expand and contract as temperatures change. Rock wool is extremely stable and moves approximately 10 times less than polyiso rigid foam. This stability ensures the boards stay tight together without forming gaps.

Rigid foam is prone to shrinking over time or shifting as temperatures fluctuate. This movement can pull seams apart and break the protective seal. Foam installations rely on tape to seal these seams, which can peel or degrade and let water through.

Stone wool fibers are also naturally hydrophobic, meaning they repel water rather than absorbing it. They are non-capillary, so they do not wick water upwards. Any bulk water that gets behind the cladding drains away quickly rather than soaking into the board.

Premium Rock Wool Insulation for Industry & بناء

الصوف الصخري مقابل. Rigid Foam on Fire Safety, متانة & Environmental Impact

In simple terms: Rock wool is like a stone that refuses to burn, making it safer for tall buildings, while rigid foam is a plastic that can catch fire and often requires special shields to meet safety codes.

| ميزة | الصوف الصخري (الصوف الحجري) | Rigid Foam (XPS/EPS) |

|---|---|---|

| Fire Classification | Non-Combustible (Won’t burn) | Combustible (Can burn) |

| Heat Tolerance | Up to 1,800°F (982درجة مئوية) | Melts/ignites at much lower temps |

| Fire Code Rules | Often exempt from complex testing | Requires thermal barriers (NFPA 285) |

| Material Basis | Natural stone and recycled slag | Petrochemical plastics |

Fire Resistance and Code Compliance

Rock wool acts exactly like the stone it is made from. When exposed to fire, it sits there without burning, melting, or creating smoke. It can withstand extreme heat up to 1,800°F because it is inorganic.

Rigid foam is made of plastic, which acts like solid fuel during a fire. Because it burns easily, building codes usually require it to be covered by a thermal barrier like steel or thick drywall. This delays the foam from igniting and spreading flames up the wall.

For tall buildings over 40 feet, using foam triggers strict safety tests known as NFPA 285. Rock wool often skips these extra hurdles because it adds zero fuel to the building. This makes it a simpler choice for architects designing high-rise structures.

Material Stability and Environmental Impact

Think of rigid foam like a balloon filled with special gas. Over time, that gas can leak out, causing the foam to lose some of its insulating power or change shape. This shrinking or warping can create gaps in the wall where heat escapes.

Rock wool is chemically inert and keeps its shape indefinitely. It does not shrink or off-gas because it is not made with blowing agents. This means the insulation value you install today is the same value you will have in fifty years.

From an environmental view, rock wool uses recycled steel slag and natural rock. Many foams rely on chemicals that have a higher potential to warm the planet. By using stone instead of plastic, rock wool avoids these specific chemical risks.

الصوف الصخري مقابل. Rigid Foam on Installation, Labor & Total Project Cost

In simple terms: Rigid foam works like lightweight poster board that is fast and cheap to hang, while rock wool is like installing heavy stone tiles that cost more and take extra muscle to secure.

Comparing Material Prices and Installation Labor Dynamics

Rigid foam is generally the clear winner when looking at the price tag. The material costs usually fall between $0.25 و $2.00 per board foot depending on the specific product. This makes it a very budget-friendly option for covering large areas quickly.

Rock wool boards come with a higher upfront cost. You can expect to pay between $0.80 و $1.50 per square foot just for the boards themselves. The raw materials used to make stone wool are simply more expensive to produce than plastic foam.

The physical work required to install them is also very different. Rigid foam comes in large 4×8 foot sheets that are light and easy for one person to carry. Workers can cut them with a basic knife and tape the seams together in minutes.

Total Installed Cost Analysis per Square Foot

When you combine material and labor, rock wool is the premium option. The total installed cost typically lands between $1.40 و $4.00 per square foot. Complex wall designs will push that number toward the higher end.

Rigid foam offers a better return on investment strictly for insulation power. It delivers an R-value of 5 ل 6.5 لكل بوصة, while rock wool provides an R-value of 3.0 ل 4.2. This means you get more thermal protection for every dollar you spend on foam.

This difference also impacts the thickness of your walls. To meet building codes, you would need a thicker layer of rock wool compared to rigid foam. This adds to the material volume and can affect the overall building design.

Builders often choose rock wool despite the higher price. Many projects accept total costs that are 10% ل 40% higher because they need specific safety features. If a building requires non-combustible materials or walls that allow vapor to escape, the extra cost is worth it.

When to Choose Rock Wool (And When XPS/EPS Is the Better Choice)

In simple terms: Use Rock Wool for exterior walls that need to resist fire and allow moisture to escape, acting like a breathable stone shield. Choose XPS foam for basements and heavy floors where the material must block water and support heavy weight, acting like a waterproof raft.

| Application Scenario | Best Choice | Why It Wins |

|---|---|---|

| Fire-Critical Zones | الصوف الصخري | غير قابلة للاحتراق; resists heat >1,000درجة مئوية. |

| الطوابق السفلية & Wet Soil | XPS Foam | Waterproof structure; absorbs <0.3% water. |

| Noisy Environments | الصوف الصخري | Dense fibers trap sound waves effectively. |

| Under Concrete Slabs | XPS Foam | High compression strength (ما يصل الى 100 psi). |

| Humid Climates | الصوف الصخري | Highly permeable; lets walls dry out. |

Best Use Cases for Rock Wool: السلامة من الحرائق & Vapor Permeability

Think of Rock Wool like a heavy wool sweater for your house. It keeps the heat in, but it also allows moisture from inside the house to escape so you do not get clammy walls. It is the best choice when safety and drying are your main goals.

This material is mandatory for buildings that must meet strict fire codes. Rock wool can withstand temperatures over 1,000°C without melting or catching fire. This makes it a critical safety layer for exterior walls.

It is also the superior choice for noisy areas, such as city apartments or buildings near highways. The dense fiber structure traps sound waves much better than rigid foam. This creates a quieter and more peaceful indoor environment.

أخيراً, choose rock wool when your wall design needs to “breathe.” In humid climates, moisture often gets trapped inside walls. Rock wool allows this vapor to pass through and evaporate, which helps prevent dangerous mold growth.

Best Use Cases for XPS/EPS: Below-Grade & High-Load Applications

Think of XPS foam like a surfboard. انها خفيفة الوزن, very strong, and completely waterproof even when it sits in water for a long time. This makes it the champion for any insulation that touches the ground.

XPS is the standard choice for basements and foundations. Because of its closed-cell structure, it absorbs almost no water (only about 0.3%). This keeps your basement dry and warm even if the soil outside is soaking wet.

You should also use XPS for floors that need to hold heavy weight, like a garage or an industrial warehouse. It has high compressive strength, meaning it can support up to 100 psi without getting squashed. This is essential when pouring heavy concrete slabs over the insulation.

For projects with a tight budget, EPS (expanded polystyrene) is a good alternative. It is not as strong or water-resistant as XPS, but it costs less. It works well for simple exterior updates where the insulation does not need to support heavy loads.

How to Select the Best Exterior Wall Insulation for Your Building Project

In simple terms: Choosing the right material is a trade-off between size and safety. If you have very little space, pick rigid foam because it is thin and powerful. If you want a building that naturally resists fire and allows damp walls to dry out, pick rock wool.

Defining Project Constraints: Climate Zones and Wall Thickness

Your first step is checking the rules for your specific location. The Department of Energy (DOE) sets minimum insulation targets, known as R-values, that change based on how cold your climate is. You need to know this target number before you look at materials.

Once you have your target, look at the physical space available in your walls. Rigid foams like XPS or Polyiso are very dense, meaning they provide high heat resistance in a very thin board. This is like wearing a high-tech, thin thermal jacket that keeps you warm without bulk.

Rock wool works differently and requires more thickness to do the same job. If you are renovating an old building where every inch of floor space counts, the thinner profile of rigid foam might be necessary. You often pay more for foam, but it saves valuable room inside the building.

Weighing Performance Priorities: السلامة من الحرائق, Moisture Control, and Budget

You must decide if fire safety is your absolute top priority. Rock wool is made from actual stone, so it cannot burn and does not need special chemicals to be safe. This makes it the standard choice for high-rise buildings where fire codes are very strict.

Water handling is another major difference between these materials. Rigid foams act like a plastic barrier that stops water completely, which is perfect for basements or wet soil conditions. Rock wool is more like a wool sweater; it breathes and lets water vapor escape, which helps damp walls dry out to prevent rot.

أخيراً, look at your environmental goals and budget. Standard foams can be cheaper but often use chemicals that are harder on the environment. Rock wool is generally considered more eco-friendly because it is made from recycled slag and natural rock, though it may cost more to install due to its weight.

About Chinathermalinsulation Company

In simple terms: Chinathermalinsulation Company is a large manufacturer and rockwool manufacturers that turns rock and minerals into fire-proof insulation for buildings and factories, similar to how a bakery turns flour into bread but for industrial safety.

Manufacturing Infrastructure and Customization Capabilities

The company runs a massive factory that covers 40,000 متر مربع. This large space allows them to turn raw minerals into strong fibers and shape them into final products. It is equipped with special machines to handle the high heat needed for processing.

They have a team of over 26 engineers who help design these products. This means they can make insulation in specific shapes, weights, or sizes depending on what a customer needs. It is like ordering a custom-fitted suit instead of buying one off the rack.

Their machines produce flexible blankets, hard boards, and hollow pipes. These parts are designed to fit perfectly around industrial furnaces or inside building walls. This variety ensures they have the right “shield” for any type of equipment.

They use special technology to make fibers that are safer for workers to handle. This process also lowers harmful chemicals like chloride. It makes the insulation better for the environment and safer for the people installing it.

Technical Standards, الشهادات, and Performance Metrics

Their products follow strict international rules like ASTM C612 and EN13501. These rules act like a report card that proves the insulation works correctly. It confirms the material is safe to use in homes and commercial buildings.

The rock wool they make is very effective at stopping heat from moving. It has a specific rating that shows it keeps heat in or out very efficiently. This helps building owners save money on energy bills over time.

They hold important certificates like ISO9001 and CE. Think of these as a seal of approval that proves every batch they make meets high safety standards. It ensures the quality stays the same with every order.

They formulate the insulation to be dense and heavy. This extra weight helps block loud noises from passing through walls. It also stops fire from spreading for a longer time, giving people more safety during an emergency.

الأسئلة المتداولة

How does the moisture permeability of rock wool prevent rot in wall assemblies?

Rock wool acts like a breathable sports shirt for your building. It is 98% porous, which allows water vapor (like steam) to pass right through it, even while it blocks liquid water.

This lets any dampness trapped inside your walls escape and dry out naturally. By letting the wall “breathe,” it keeps the wood studs and sheathing dry.

In contrast, foam insulation acts more like a plastic bag. It can trap moisture inside the wall cavity, which keeps things damp and significantly increases the risk of rot over time.

What is the typical percentage of R-value reduction in XPS over 15 years?

The answer depends heavily on how wet the foam gets. In dry laboratory tests, XPS foam loses very little of its insulating power (قيمة R) over time.

لكن, real-world tests tell a different story, especially in wet underground areas. XPS foam can lose about 50% of its warmth-keeping power after 15 years because it absorbs water.

Rock wool is different because it repels water naturally. It maintains its stable thermal performance forever, regardless of how much time passes.

Is rock wool board cost-effective for retrofitting existing commercial facades?

نعم, especially when you look at the long-term costs. While the material itself costs $6–$9 per square foot, it saves money in other critical areas.

على سبيل المثال, rock wool is naturally fireproof. This means you do not need to buy and apply the expensive fire-safety coatings that foam insulation requires.

You also save on energy bills every year. Over 30 years, these energy savings and lower maintenance costs typically deliver a solid 5–6% return on your investment.

What is the impact of sunlight (UV exposure) on the installation process for rock wool vs. XPS?

Sunlight acts like kryptonite for foam insulation, but it is not an issue for rock wool. If XPS foam sits in the sun for more than 30 ل 60 أيام, it starts to degrade and turn into dust.

This forces builders to race against the clock. They must schedule strict protective coverings to prevent the surface from getting damaged.

Rock wool handles the sun much better. It might change color slightly, but it stays strong and keeps its insulating power even during long construction delays.