Lassen Sie uns den Zauber hinter den flauschigen Decken und starren Brettern enthüllen, die unsere Gebäude gemütlich machen, Maschinen summten, und Industrieanlagen sicher – ohne wie ein Laborhandbuch zu klingen! Der Isolationsprozess ist eine faszinierende Reise: wo einfache Felsen, Glas, oder Schäume verwandeln sich in Hochleistungsschaumstoffe, stabile Materialien.

Wir beleuchten den Herstellungsprozess von Isoliermaterial, Vergrößern Sie das Innere, wie Steinwolle in der Fabrik entsteht, und warum jede Phase wichtig ist. Dies ist ein Fabrikabenteuer – gespickt mit technischer Präzision.

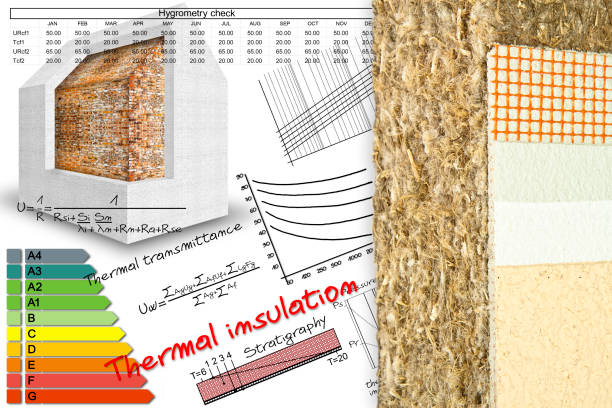

Welche Materialien werden in der technischen Isolierung verwendet??

Wolle auf Mineralbasis (Steinwolle & Glaswolle)

- Steinwolle (Steinwolle)

Die Hauptzutaten werden aus Basalt oder Diabas gewonnen und oft mit recycelten Mineralien gemischt, um Leistung und Nachhaltigkeit zu optimieren.

Nicht brennbar gemacht, Steinwolle wird für ihre Feuerbeständigkeit geschätzt (oft mit Euroklasse A1 bewertet), ausgezeichnete thermische und akustische Kontrolle, und robuste Dimensionsstabilität.

Zu den gängigen Formaten gehören dichte Bretter und flexible Decken, in Gebäudehüllen verwendet, industrielle Rohrleitungen, Schalldämmung, und Feuerschutzbarrieren.

- Glaswolle

Zu den Rohstoffen gehört recyceltes Glas, Sand, Kalkstein, und Soda. Die Mischung wird geschmolzen und zu feinen Glasfasern gesponnen, die an „Zuckerwatte“ erinnern..

Die thermische Leistung entsteht durch das Einschließen von Millionen winziger Lufteinschlüsse in den Fasern, Bietet eine hervorragende Isolierung mit kontrollierter Dichte.

Hergestellt durch Faserung, Bindemittelspray, Aushärten (oft in der Nähe 200 °C), Anschließend erfolgt das Kalandrieren und Schneiden in Platten oder Rollen.

Polymerschäume & Sprühsysteme

- Polyisocyanurat (PIR) & Polyurethan (PUR) Schäume

Chemie: PIR entsteht bei MDI (Methylendiphenyldiisocyanat) polymerisiert und reagiert mit Polyol, starr bilden, hochvernetzte Schäume, die hohen Temperaturen standhalten und sich langsam abbauen (Beginn oberhalb ~200 °C).

Bei der Herstellung werden Isocyanat und Polyol mit Treibmitteln vermischt, Anschließend Formen oder kontinuierliche Herstellung von Schaumstoffplatten oder -platten.

Anwendungen: Sandwichplatten, vorisolierte HVAC-Leitung, Kühlräume – überall, wo es schlank ist, Eine effiziente Isolierung ist der Schlüssel.

Spezialisolierungen

Hergestellt aus Aluminiumoxid-Siliziumoxid-Schmelzen, die zerfasert und zu leichten Matten geformt werden – ideal für extreme Hitzeanwendungen wie Öfen und Brennöfen.

- Aerogele & VIPs

Aerogeldecken kombinieren eine extrem niedrige Wärmeleitfähigkeit und ein leichtes Profil, Perfekt für nachrüstbare Räume. Vakuumisolierte Paneele (VIPs) bieten unübertroffene Isolierung pro Dicke, erfordern jedoch eine sorgfältige Konstruktion, um die Vakuumintegrität aufrechtzuerhalten.

Wie wird Steinwolle hergestellt – Schritt für Schritt?

Rohstoffe & Schmelzen

- Zutaten: Hochwertiger Basalt oder Diabas, oft ergänzt mit recyceltem Mineral oder Schlacke, um sowohl Nachhaltigkeit als auch Kosteneffizienz zu gewährleisten.

- Schmelzvorgang: Wird in koksbefeuerten oder elektrischen Öfen bei ca. 1.400–1.500 °C durchgeführt, um eine gleichmäßige Schmelze und faserfertige Viskosität sicherzustellen.

Faserbildung & Schussentfernung

- Faserbildung: Der geschmolzene Strom wird durch Hochgeschwindigkeitszentrifugalschleudern oder -düsen gepresst, lange erstellen, feine Fasern.

- Schussentfernung: Zyklone und Siebe extrahieren unzerfaserte Tröpfchen („Schüsse“), Dies gewährleistet thermische Leistung und Produktgleichmäßigkeit.

Bindemittel & Zusatzstoffe

- Bindemittel: Ein feiner Phenol- oder emissionsarmer Harznebel wird auf die Fasern gesprüht, um sie zu binden – ohne die Feuerbeständigkeit zu beeinträchtigen.

- Zusatzstoffe: Zur Verbesserung der Feuchtigkeitsbeständigkeit und Haltbarkeit können wasserabweisende Öle oder Silikone zugesetzt werden.

Mattenbildung & Vorpressen

- Bildung: Fasern fallen auf ein Förderband oder Band, Bilden einer gleichmäßigen Matte mithilfe oszillierender Köpfe und Luftstromsteuerung.

- Vordrückung: Die Matte wird komprimiert, um die Schüttdichte und Dicke zu kontrollieren, Vorbereitung für die Aushärtung.

Heilung, Kühlung, & Stabilisierung

- Ofenheilung: Die Matten durchlaufen Heißluftöfen (typischerweise 180–250 °C), Aushärten des Bindemittels und Fixieren der Struktur.

- Kühlung: Kontrollierte Kühlung reduziert innere Spannungen und sorgt für Dimensionsstabilität nach dem Aushärten.

Konvertierung, Verkleidungen & Endgültige Fertigstellung

- Schneiden & Gestaltung: Bretter, Rohrabschnitte, oder Lamellen werden mit Sägen oder Spezialmaschinen präzise geschnitten.

- Verkleidungen: Optionale Laminate – wie zum Beispiel Folie, Glasschleier, Kraftpapier, oder Polymerfolien – werden zur Dampfregulierung eingesetzt, Reflexionsvermögen, oder einfache Handhabung.

Qualitätssicherung & Verpackung

- Testparameter: Wärmeleitfähigkeit (Lambda), Dichte, Dicke, Druckfestigkeit, Wasseraufnahme, Faserdurchmesser, Schussinhalt, und Feuerverhalten werden alle überprüft.

- Verpackung: Komprimiert oder verpackt, mit Chargenangaben beschriftet, und palettiert – versandbereit mit Rückverfolgbarkeit.

Firmenvorstellung: Wer wir sind

RPOWER (Shijiazhuang SOBO Commercial Co., Ltd.) ist ein erfahrener Akteur im Bereich Wärmedämmung, gegründet in 2013 und mit Sitz in Shijiazhuang, China.

Was uns auszeichnet:

- Spezialisierte Fertigung & globaler Handel

Wir produzieren Steinwolle, Glaswolle, und Keramikfaserisolierung – und bieten sowohl OEM- als auch ODM-Anpassungen an, die auf Ihre Bedürfnisse zugeschnitten sind.

- Modernste Fertigungsleistung

Unsere Isolierprodukte bieten außergewöhnliche Leistung – Wärmeleitfähigkeit so niedrig wie 0.032 W/(m · k)– dank ultrafeiner Fasertechnologie, geringe Dichten, und vielseitige Formate wie Decken, Bretter, und Rohre.

- Qualität, Sicherheit, und Nachhaltigkeit zuerst

Wir arbeiten mit integriertem Recycling, Priorisieren Sie die Arbeitssicherheit, und validieren unsere Produkte durch unabhängige Drittlabore. Zertifizierungen (SGS, MSDs) und die Einhaltung der EN/ASTM-Normen sind für uns selbstverständlich.

- Globale Reichweite & Branchenvielfalt

RPOWER bietet Isolationslösungen branchenübergreifend, einschließlich Gebäude, Industrieausrüstung, Transport, Energie, und spezielle Anwendungen für extreme Umgebungen.

FAQs

1. Was ist der Unterschied zwischen dem Isolationsprozess und dem Herstellungsprozess von Isolationsmaterial??

Sie sind zwei Seiten derselben Medaille. Der Isolationsprozess bezieht sich auf die Funktionsweise des Materials (Wärme einfangen, Feuer widerstehen, Reduzierung von Lärm), während der Herstellungsprozess von Isoliermaterial die Schritte erfasst – das Schmelzen, Faserbildung, Aushärten, Tests – die Roheingaben in Endprodukte umwandeln.

2. Kann RPOWER Isolierungsformate anpassen??

Absolut! Wir bieten maßgeschneiderte ODM/OEM-Dienstleistungen für die Lieferung von Steinwolle, Glaswolle, und Keramikfasern in Formaten wie Decken, Bretter, und Rohre, die perfekt zu Ihren Projektanforderungen passen.

3. Wie gewährleistet RPOWER Qualität und Sicherheit??

Wir nutzen integrierte Recyclingsysteme, sichere Designmerkmale, und unabhängige Tests (EN/ASTM-Standards), mit Zertifizierungen wie SGS und MSDS, die eine Validierung durch Dritte ermöglichen.

4. Welche Isolierungsarten eignen sich für Umgebungen mit hohen Temperaturen??

Für extrem hohe Temperaturen, Keramikfasern (Alumo-Silikat-Wolle) sind die erste Wahl. Rockwool bewältigt auch moderate Hochtemperaturszenarien mit beeindruckender Leistung.

Abschluss

Was für eine Reise! Vom geschmolzenen Gestein bis zur widerstandsfähigen Isolierung, Jeder Schritt im Herstellungsprozess von Isoliermaterial vereint technische Präzision mit strenger Qualitätskontrolle. Technische Materialien – von Steinwolle über Glaswolle bis hin zu Polymerschäumen – sind auf die Wärmedämmung zugeschnitten, akustisch, Feuer, und Feuchtigkeitsleistung.

Hinter den Kulissen, Der Isolationsprozess entfaltet sich als Symphonie des Hochtemperaturschmelzens, Faserbildung, Bindung, Aushärten, und Qualitätskontrollen. Das Ergebnis? Zuverlässig, Hochleistungsisolierung, der Sie vertrauen können.