Commercial acoustic design fails when engineering teams treat sound absorption and noise isolation as interchangeable metrics. While typical wall assemblies might block transmission, controlling internal reverberation demands specific material properties to ensure speech intelligibility and occupant comfort. Bei China Thermal Insulation, we provide engineered rock wool insulation solutions that meet stringent acoustic and fire-safety standards—explore our full range at https://chinathermainsulation.com/

to support your next commercial or industrial project.

We examine how rock wool’s fiber matrix controls sound energy, detailing the density requirements—from 45 kg/m³ to 140 kg/m³—needed to effectively manage low-frequency noise. This guide breaks down the correlation between material thickness and NRC targets of 0.80–1.00, providing actionable data on achieving compliance with ASTM C423 testing standards and HUD multi-family noise codes.

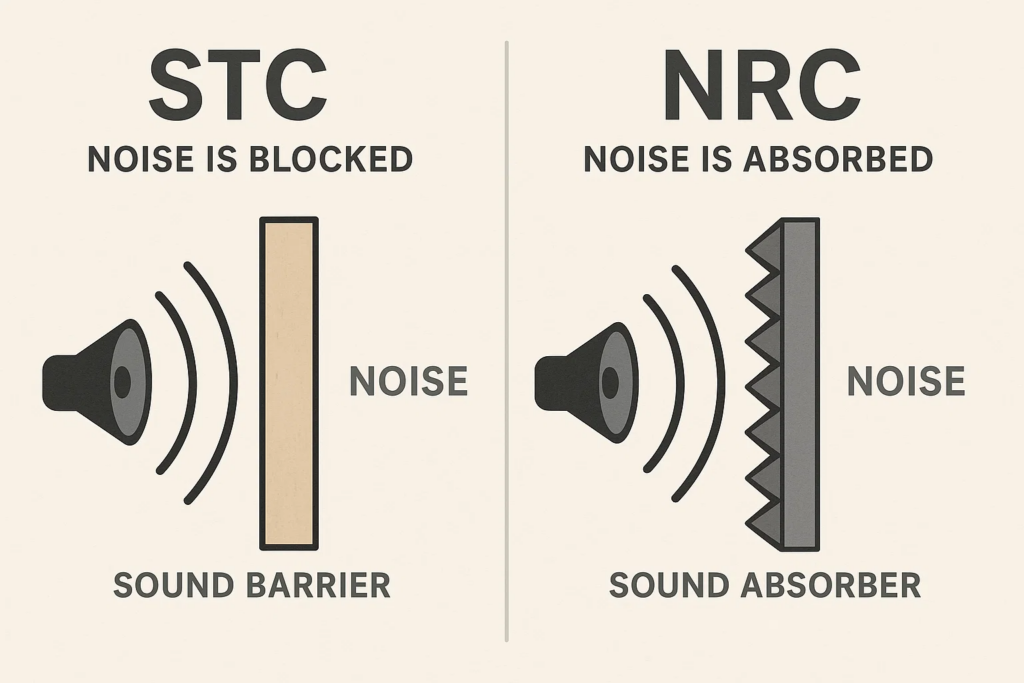

The Science of Sound Absorption: STC vs. NRC

NRC (Noise Reduction Coefficient) measures how much sound a material absorbs within a room to reduce echo, rated on a scale of 0.0 Zu 1.0. In contrast, STC (Sound Transmission Class) quantifies how effectively a wall or partition blocks airborne sound from passing between rooms. While NRC controls internal acoustics, STC dictates noise isolation.

Defining the Core Metrics: Absorption (NRC) vs. Isolation (STC)

Acoustic engineering relies on two distinct metrics to solve different problems: Noise Reduction Coefficient (NRC) and Sound Transmission Class (STC). NRC acts as the primary indicator for internal room acoustics, measuring the percentage of sound energy a surface absorbs rather than reflecting it back into the space. A material with an NRC of 1.0 absorbs 100% of incident sound, effectively eliminating reflections, whereas a surface with an NRC of 0.0, such as concrete, reflects sound and generates reverberation.

In contrast, STC serves as the standard for “building acoustics” and isolation. It measures the decibel reduction of airborne sound as it passes through partitions like walls, windows, or doors. Effective acoustic design requires distinguishing between these needs. For instance, high NRC values are essential for speech intelligibility in open-plan offices, while high STC ratings are necessary to ensure privacy between adjacent hotel rooms or sensitive conference areas.

How Rock Wool’s Density and Fiber Structure Control Sound

Rock wool controls sound through porous absorption, where its dense, randomly oriented fiber matrix (typically 45–140 kg/m³) creates high airflow resistance. As sound waves penetrate the material, the fibers generate viscous friction, converting acoustic energy into heat. Increasing density and thickness significantly boosts NRC values from ~0.70 to >1.10, particularly improving low-frequency damping compared to lighter fiberglass alternatives.

| Density Profile (kg/m³) | Material Thickness | Typical NRC | Primary Acoustic Application |

|---|---|---|---|

| Standard (RWA45 ≈ 45 kg/m³) | 25 mm (1″) | 0.70 – 0.80 | General speech clarity and partitions. |

| Mid-Range (RW3 ≈ 60 kg/m³) | 50 mm (2″) | 1.05 – 1.10 | Broadband absorption for studios/offices. |

| Heavy Duty (RW6 ≈ 140 kg/m³) | 50–100 mm (2–4″) | > 1.10 | Low-frequency damping and mechanical noise. |

The Physics of Porous Absorption and Fiber Matrix

Rock wool functions as a porous absorber, utilizing a random network of mineral fibers to trap incident sound waves. Unlike reflective surfaces that bounce noise back into a room, this fibrous structure allows sound pressure to penetrate deep into the material. The absorption mechanism relies on viscous friction and airflow resistance. As air particles vibrate within the dense fiber matrix, the friction against the mineral strands converts kinetic acoustic energy into heat, dissipating the sound energy.

The random orientation of the fibers creates a tortuous path for sound waves. This complex internal geometry is more effective at broadband absorption than uniform structures because it forces sound waves to interact with a larger surface area of fiber. This process significantly reduces reverberation time in the surrounding space, making it a critical component for controlling echo and speech intelligibility.

Installation Techniques for Maximum Sound Damping

Maximizing sound damping requires strategic installation techniques that go beyond material selection. Creating specific air gaps behind panels, known as ASTM E795 Type E200 or E400 mountings, significantly improves low-frequency absorption. Außerdem, eliminating flanking paths through airtight sealing with neoprene weatherstripping and acoustical caulk ensures the assembly achieves its rated STC performance.

Optimizing Air Cavities and Mounting Depths

Standardized mounting practices dictate how acoustic materials perform in real-world scenarios compared to laboratory tests. ASTM E795 defines specific mounting configurations, such as Type A for direct mounting to a rigid backing and Type E400 for panels installed with a 400 mm (approximately 16 inches) air space behind them. These designations allow consultants to predict how an absorber will behave when installed over a plenum or suspended ceiling rather than glued directly to a wall.

Introducing an air cavity behind a porous absorber fundamentally alters its acoustic performance by shifting absorption efficiency toward lower frequencies. A cavity depth of 200 mm to 400 mm moves the particle velocity maximum of the sound wave into the resistive material, effectively capturing longer wavelengths associated with mechanical equipment. For mechanical rooms and industrial spaces, utilizing these Type E mounting configurations aligns installed performance with the low-frequency requirements often missed by standard NRC ratings.

Sealing Flanking Paths and Mechanical Decoupling

Blocking airborne sound relies on the integrity of the barrier, making airtight seals critical for maintaining high STC ratings. Small openings or gaps create flanking paths that allow sound to bypass the assembly entirely. For operable components like doors and windows, durable neoprene weatherstripping applied to all four sides provides a compressed, airtight seal, whereas porous felt materials often fail to stop sound leakage.

Physical decoupling prevents vibration transfer between finish layers and the structural framing. Techniques such as using resilient channels, staggered studs with 2×6 framing, or wire-suspended ceilings break the direct path for structure-borne noise. This isolation is particularly important in high-performance walls where rigid connections would otherwise bridge the damping layers and degrade the assembly’s overall isolation capability.

Penetrations for utilities pose another risk for sound leakage and must be addressed during construction. Ducts and pipes insulation should run straight and connect securely, with all joints and annular spaces fully caulked to eliminate gaps. Proper sealing of these penetrations ensures that the wall assembly functions as a continuous barrier, preserving the acoustic isolation intended by the design.

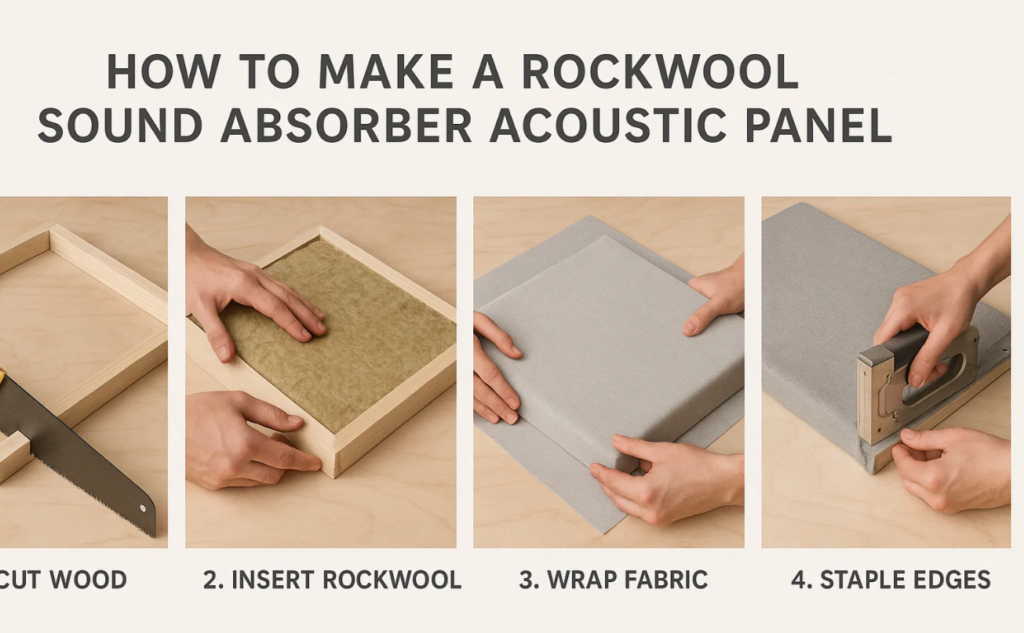

Comparing Acoustic Rock Wool Batts vs. Acoustic Panels

Acoustic rock wool batts, with densities of 40–80 kg/m³, outperform panels in low-frequency absorption and STC ratings (45–52), making them ideal for mechanical noise control. In contrast, fiberglass acoustic panels offer lighter weight and rigid structures for easier, frameless installation in general office spaces, though they often lack the extreme heat resistance (>1000°C) and bass trapping capabilities of mineral wool.

Engineering Profile: Dichte, NRC, and Low-Frequency Performance

Mineral wool batts feature higher density configurations, typically ranging from 40 Zu 80 kg/m³. This increased mass results in superior Sound Transmission Class (STC) ratings of 45 Zu 52, providing stronger isolation capabilities than lighter fiberglass alternatives. While fiberglass panels achieve competitive Noise Reduction Coefficient (NRC) ratings between 0.90 Und 0.95, mineral wool reaches up to 1.05 NRC. This performance gap is most distinct in the absorption of frequencies under 250 Hz, where density plays a critical role in attenuation.

The fibrous, non-rigid structure of rock wool creates effective friction-based energy conversion, making it the preferred material for bass trapping in industrial settings. Fiberglass panels rely on rigidity to hold their form, a design trade-off that sacrifices the mass required to effectively block heavy mechanical vibration and low-end noise transmission.

Operational Suitability: Installation, Brandschutz, and Long-Term Durability

Steinwolle batts withstand temperatures exceeding 1000°C and meet ASTM E136 standards for non-combustibility, offering superior safety for high-heat industrial zones compared to standard fiberglass. Long-term durability also favors mineral wool, which retains its shape without sagging. Fiberglass panels often face issues with settling or degradation when exposed to moisture, which can alter their acoustic properties over time.

Installation speed favors fiberglass panels due to their rigid, frameless design that allows for direct mounting. Mineral wool requires framing and wrapping to contain fibers, increasing the complexity of the assembly. Consequently, engineers specify rock wool for hidden cavity fills and fire walls where structural resilience is paramount, while panels typically serve as surface-mounted aesthetic treatments for controlling reverberation in offices and commercial spaces.

High-Performance Rock Wool Insulation Solutions

Specifying for Multi-Family Noise Codes

Multi-family noise codes generally follow HUD standards, which define acceptable exterior noise at 65 Ldn or lower and mandate a maximum interior noise level of 45 decibels. Projects in ‘Normally Unacceptable’ zones (65-75 Ldn) require additional attenuation of 5 Zu 10 decibels beyond standard construction to meet code.

HUD Exterior Noise Standards and Interior Goals

The Department of Housing and Urban Development (HUD) establishes the regulatory baseline for residential noise control through a three-tier classification system. The foundational standard defines an exterior noise exposure of 65 Day-Night Average Sound Level (Ldn) or lower as “Acceptable.” At this level, standard building construction is assumed to provide sufficient sound damping to achieve the required interior noise limit of 45 decibels without specialized intervention.

Sites exceeding this baseline face stricter classifications that impact design specifications. Exterior exposure levels falling between 65 Und 75 Ldn are categorized as “Normally Unacceptable,” while levels exceeding 75 Ldn are deemed “Unacceptable.” Identifying these zones early in the site planning phase is critical, as projects located in higher decibel zones must incorporate specific acoustic treatments to permit residential development.

Attenuation Requirements for High-Decibel Zones

Projects located within the “Normally Unacceptable” range must demonstrate enhanced sound isolation capabilities to meet federal standards. The regulations mandate a graduated approach to attenuation based on the severity of the noise exposure. For sites measuring between 65 Und 70 Ldn, the building envelope must provide at least 5 decibels of additional attenuation beyond what standard construction offers. If the site exposure rises to the 70 Zu 75 Ldn band, the requirement increases to 10 decibels of additional attenuation.

Verifying compliance requires precise measurement using instrumentation calibrated to ANSI S1.4-1971 standards. These assessments must utilize an A-weighted scale with a fast meter response. To capture the full acoustic profile of a site, the integration protocols must account for all continuous, intermittent, and impulsive sound sources falling within the 80 Zu 130 decibel range.

Häufig gestellte Fragen

How much does a small gap in insulation affect the overall STC rating?

Small gaps significantly degrade STC performance by providing a direct bypass for airborne sound. Even minor openings negate the benefits of mass and damping, effectively lowering the wall’s rating closer to that of the gap itself. Complete perimeter sealing is essential to maintain the integrity of the assembly.

Does the density of the facing (Z.B., fiberglass scrim) impact the NRC?

Ja, facing density directly influences sound absorption. High-density fiberglass scrims typically result in NRC ratings between 0.75 Und 0.85 when paired with a 6-7 pcf core. While these facings provide durability, they must remain acoustically transparent enough to allow sound waves to penetrate the fibrous core for effective dissipation.

What are the key sound frequency targets for commercial building codes?

Commercial codes primarily target the 125 Hz to 4000 Hz range using STC ratings, with the IBC mandating a minimum of STC 50 for multifamily units. Jedoch, critical low-frequency mechanical noise (63 Hz and 80 Hz) often falls outside standard STC testing, requiring additional mitigation strategies like OITC ratings or specialized low-frequency isolation.

What is the typical STC gain when adding rock wool to a standard drywall assembly?

Adding rock wool or mineral wool to a standard cavity typically improves the assembly’s STC rating by 5 Zu 10 points. This increase results from the insulation absorbing cavity resonance, which helps reduce the sound energy transmitting through the hollow space between studs.