Commercial projects demand a careful balance between meeting immediate budget caps and ensuring long-term structural safety. Fiberglass provides an accessible entry point with installed costs ranging from $0.60 Zu $1.20 per square foot, making it the standard choice for cost-conscious residential envelopes. In contrast, rock wool justifies its higher investment through superior fire containment, resisting melting points up to 2,150°F while maintaining its form for decades.

This guide evaluates the technical specifications defining both materials, from R-value consistency to acoustic performance differences. We examine how moisture impacts material longevity and analyze the specific wall assemblies where rock wool’s durability outweighs the lower upfront cost of fiberglass.

Comparison Overview: Kosten, R-Wert, and Longevity

Rockwool costs $1.50–$2.00 per square foot installed, delivering an R-Wert of 4.0 per inch and retaining structural integrity for 30+ years. Fiberglass is more affordable at $0.60–$1.20 per square foot with lower R-values (2.2–3.8 per inch) and a shorter 15–25 year lifespan due to potential sagging and moisture absorption.

| Comparison Metric | Steinwolle (Steinwolle) | Fiberglas |

|---|---|---|

| Installed Cost (sq. ft.) | $1.50 – $2.00 | $0.60 – $1.20 |

| R-Wert (Per Inch) | ~4.0 (High Density) | 2.2 – 3.8 (Variable) |

| Expected Lifespan | 30+ Years | 15 – 25 Years |

| Structural Stability | Rigid, Non-Sagging | Flexible, Prone to Sagging |

Installation Costs and Market Pricing Analysis

Fiberglass functions as the budget standard for residential insulation, typically costing between $0.60 Und $1.20 per square foot for installed applications. This price point minimizes immediate capital expenditure, making it the primary choice for standard renovations where upfront affordability outweighs long-term performance metrics.

Rockwool commands a significant price premium of 150% Zu 250%, with installed costs ranging from $1.50 Zu $2.00 per square foot. This higher cost directly correlates to the material’s density and manufacturing complexity. Thickness plays a major role in the final invoice; standard 1-inch boards average $1.20 Zu $1.40 per square foot, while heavy-duty 3-inch industrial slabs often exceed $1.70 Zu $2.00 per square foot.

Builders and homeowners must weigh these financials based on the project’s horizon. Fiberglass offers the lowest barrier to entry, whereas rockwool is priced as a long-term structural investment designed to reduce maintenance and energy costs over the building’s entire lifecycle.

Thermische Effizienz (R-Wert) and Structural Lifespan

Rockwool consistently achieves an R-value of 4.0 pro Zoll, delivering superior thermal resistance with less material depth. This efficiency allows builders to meet strict energy codes without increasing wall thickness. In comparison, fiberglass R-values fluctuate between 2.2 Und 3.8 pro Zoll, often requiring a greater volume of material to match the thermal performance of a thinner rockwool layer.

The longevity of the materials differs significantly due to their physical composition. Rockwool maintains its engineered density and thermal properties for over 30 years without settling, ensuring consistent insulation from the roof line to the floor plate. The rigid stone fibers resist compression and gravity over time.

Fiberglas batts generally have a shorter effective lifecycle of 15 Zu 25 years. The lighter glass fibers are prone to sagging within vertical wall cavities, creating gaps that facilitate heat loss. This degradation accelerates in humid environments, where moisture absorption can compromise the loft and thermal resistance of the fiberglass matrix.

Akustische Leistung: Rock Wool’s Superior Sound Dampening (NRC)

Rock wool typically achieves a Noise Reduction Coefficient (NRC) between 0.85 Und 1.10, excelling in sound absorption due to its high density. Unlike lighter insulation, its fibrous structure effectively traps low-to-mid frequency sound waves, making it a preferred choice for studios and industrial noise control.

NRC Ratings and Low-Frequency Absorption Capabilities

Standard rock wool panels and batts consistently deliver NRC values ranging from 0.85 Zu 1.10 when tested under ASTM C423 standards. While lighter fiberglass materials perform well in the mid-to-high frequency spectrum, rock wool’s internal structure optimizes absorption for low-to-mid frequency ranges. This characteristic makes it particularly effective in environments where controlling bass resonance and lower-pitch industrial noise is critical.

Engineers frequently specify high-grade acoustic mineral wool with NRC ratings of 0.95 Zu 1.05 for specialized applications like bass traps and recording studios. Beyond raw absorption data, the material’s form stability ensures consistent performance over the building’s lifespan. Softer insulation types may sag over time, creating acoustic gaps that compromise sound isolation, whereas rock wool maintains its shape and density indefinitely.

Density Metrics and STC Performance Comparison

Optimal acoustic performance for fabric-wrapped panels typically occurs within a density sweet spot of 3–6 pcf (48–96 kg/m³). Utilizing rock wool infill in standard insulated wall systems typically elevates the Sound Transmission Class (STC) to the 45–52 range. This added mass contributes to decoupling efficiency in partitions, though the overall wall assembly design remains the primary factor for maximum sound isolation.

The higher density of rock wool also provides roughly 22–37% higher R-value per inch compared to standard fiberglass batts. This dual-purpose functionality allows builders to address thermal and acoustic requirements simultaneously without increasing wall thickness. In partitions, this added mass dampens vibration transfer more effectively than lighter alternatives, providing a perceptible reduction in sound transmission between rooms.

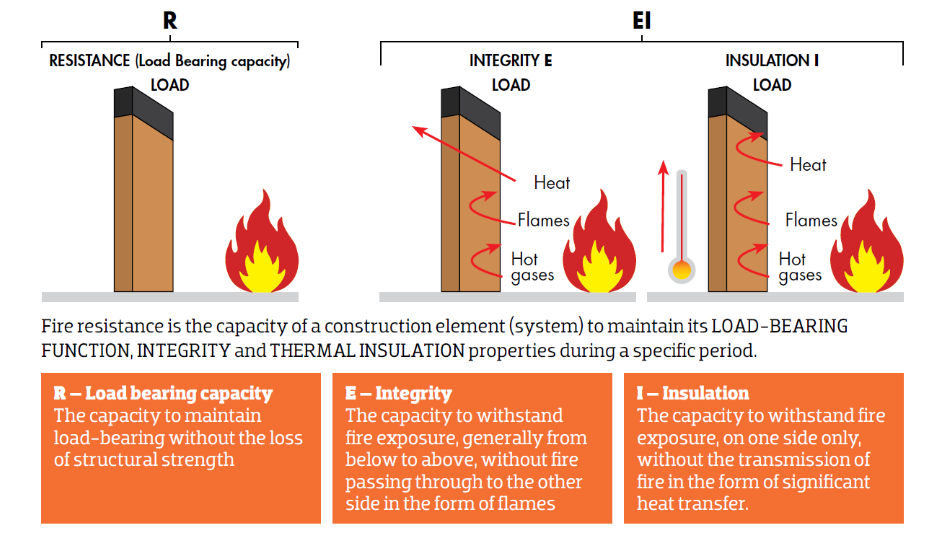

Fire Resistance Face-Off (Non-Combustible vs. Melting Point)

While both materials hold non-combustible classifications, rock wool offers superior fire containment. Originating from basalt, rock wool resists melting up to 1,177°C (2,150°F) and retains its shape for hours. Conversely, fiberglass begins to shrink and lose form around 540°C (1,000°F), which can create gaps for heat and smoke to bypass the insulation.

Structural Integrity and Behavior Under Fire

Both insulation types classify as non-combustible under standards like ASTM E84 and EN 13501, meaning the fibers themselves do not burn. But non-combustibility does not guarantee that a material will stay in place during a fire. Real-world protection depends on retaining density and form. Rock wool stays rigid and effectively blocks flame spread even in intense heat because its structure does not relax or collapse.

Fiberglass batts behave differently as temperatures rise. Once the material reaches its softening temperature, it experiences significant shrinkage and “slumping.” This physical collapse can cause the insulation to fall out of the wall cavity entirely. This loss of form creates vertical channels within the wall assembly, allowing fire and hot gases to bypass the insulation layer and penetrate the structure significantly faster.

Melting Thresholds and ASTM E119 Hourly Ratings

The specific melting points of the fibers drive these performance differences. Rock wool fibers, derived from basalt and slag, resist temperatures up to approximately 1,000°C (1,800°F) to 1,177°C (2,150°F) without melting. This high thermal tolerance allows assemblies utilizing rock wool to routinely achieve 2 to 4-hour fire ratings in full-scale ASTM E119 tests.

Fiberglass typically begins to shrink at 540°C (1,000°F) and reaches its melting range between 593°C and 649°C (1,100–1,200°F). Because of this rapid loss of structural integrity at lower temperatures, fiberglass-insulated assemblies generally cap at 0.5 to 1-hour ratings. For applications requiring extended fire resistance, such as partition walls in multi-family housing or commercial buildings, rock wool provides a measurable safety margin that fiberglass cannot match.

Premium Rock Wool Insulation Direct from the Manufacturer

Moisture Management and Hydrophobic Properties

Rock wool is inherently hydrophobic, meaning it repels liquid water while allowing vapor to escape, which helps maintain R-value and structural integrity. Fiberglass is not hydrophobic; it relies on vapor retarders (facings) to prevent moisture entrapment. If fiberglass gets wet, it can trap water within its voids, leading to sagging, loss of thermal efficiency, and increased mold risk.

Hydrophobicity and Water Repellency

Rock wool fibers possess naturally water-repellent characteristics that fundamentally change how the material interacts with liquid. When bulk water contacts a rock wool batt, it beads up and drains away rather than soaking into the core of the insulation. This hydrophobic nature allows rock wool to maintain its structure and thermal resistance (R-Wert) even after exposure to temporary moisture, such as wind-driven rain during construction or minor plumbing leaks.

Fiberglass batts act differently because they are not hydrophobic by design. While the individual glass fibers do not absorb water, the fluffy matrix of the batt can trap liquid water within its air pockets if the facing is compromised. Once fiberglass gets wet, the weight of the water often causes the material to clump, sag, and lose loft. This collapse eliminates the air gaps necessary for insulation, significantly reducing thermal resistance and often requiring total replacement if the material cannot dry quickly enough.

Vapor Permeability and Mold Resistance

A key advantage of rock wool is its ability to remain vapor-permeable while repelling liquid water. This allows wall assemblies to “breathe,” letting water vapor pass through the insulation layer to dry out rather than getting trapped against sheathing or framing. Fiberglass typically relies on integrated kraft paper or foil facings to act as vapor retarders. If these barriers are punctured or installed incorrectly, moisture can bypass the facing and accumulate inside the cavity, leading to condensation issues that fiberglass cannot easily manage.

Resistance to biological growth also differs between the two materials. Rock wool is inorganic, manufactured from basalt rock and slag at temperatures exceeding 2,900°F (1,593°C), which means it provides no food source for mold or mildew. Fiberglass is also inorganic, but its fibrous structure functions as a filter that traps organic dust and pollen over time. If a fiberglass batt sags and stays damp due to poor drying potential, this trapped organic matter can support mold growth, compromising indoor air quality.

Application Matrix: Where Each Material Excels (Wände, HVAC, etc.)

Selection depends on specific assembly priorities. Fiberglass remains the standard for cost-effective residential attics and dry partitions, offering lighter weight for high R-values like R-38 or R-49. Rock wool becomes the engineering choice for fire-rated assemblies (ASTM E119), exterior continuous insulation (NFPA 285), and high-temperature mechanical systems due to its hydrophobicity and melting point exceeding 2,000°F.

| Application Zone | Fiberglass Performance | Rock Wool Performance |

|---|---|---|

| Residential Attics | Optimal: Low density prevents ceiling sag at high R-values (R-38/R-49). | Heavy: High weight per square foot can overload standard gypsum board. |

| Fire-Rated Walls | Limited: Melts ~1,100°F; typically rated for 0.5–1 hour. | Superior: Resists >2,000°F; standard for 1–4 hour ratings (ASTM E119). |

| Exterior Facades | Not Recommended: Susceptible to moisture retention and compression. | Standard: Hydrophobic and non-combustible (NFPA 285 compliant). |

| Acoustic Partitions | Basic: Provides 4–10 dB sound reduction. | Advanced: Provides 10–15 dB reduction due to higher density. |

Standard Residential and Light Commercial Envelopes

For general construction where budget and installation speed drive decisions, fiberglass dominates the market. In attic applications requiring R-38 or R-49 thermal resistance, fiberglass is the preferred material. Its lower density allows installers to achieve high R-values without exceeding the dead-load capacity of 1/2-inch or 5/8-inch gypsum ceiling boards. Equivalent thermal resistance using mineral wool batts would significantly increase weight, potentially causing drywall sagging or failure.

High-Performance Fire, Facade, and Mechanical Applications

When safety and structural integrity under extreme conditions are paramount, rock wool becomes the standard. In fire-rated assemblies, stone wool withstands temperatures exceeding 2,000°F, compared to fiberglass which softens and melts around 1,100°F. This thermal stability makes rock wool the dominant choice for ASTM E119 and UL 263 rated walls and vertical shafts, where the insulation must maintain its shape and block heat transfer for multiple hours during a fire event.

Exterior continuous insulation (CI) applications, particularly in rainscreen facades, rely almost exclusively on rock wool boards. These assemblies require materials that are non-combustible to meet NFPA 285 standards and hydrophobic to manage bulk water intrusion. Rock wool drains water away without absorbing it, whereas wet fiberglass suffers from fiber compression and significant thermal loss, making it unsuitable for open-joint cladding systems.

Letzte Gedanken

Fiberglass remains the logical choice for budget-conscious residential projects where meeting basic code requirements takes precedence over longevity. It offers a low barrier to entry and rapid installation speeds that keep production schedules moving. Conversely, rock wool stands out as the necessary investment for commercial structures and high-performance homes, providing critical fire resistance and acoustic control that lighter materials cannot match.

The decision ultimately relies on the intended lifecycle of the building. Specifying fiberglass reduces immediate overhead, but rock wool ensures the thermal envelope retains its integrity against moisture and gravity for over 30 years. Builders and architects must balance these initial savings against the value of a resilient, non-combustible structure that requires fewer repairs and delivers consistent energy performance over time.

Häufig gestellte Fragen

Does compressed fiberglass lose R-value faster than rock wool?

Ja, fiberglass loses effective R-value more readily than rock wool when compressed. Because fiberglass is less dense and air-permeable, compression reduces its ability to trap air effectively. Rock wool maintains its structure and thermal resistance better under compression due to its higher density and rigidity.

Which material performs better in exterior walls for high-humidity zones?

Rock wool is the superior choice for high-humidity environments. Its hydrophobic fibers drain water rather than absorbing it, maintaining an R-value of R-4.0 to R-4.2 per inch even in damp conditions. Fiberglass tends to trap moisture, which can degrade its R-value and promote mold growth over time.

How does thermal performance change after exposure to minor water damage?

Mineral wool experiences minimal R-value loss because it absorbs less than 1% water by volume and dries quickly, restoring its original thermal properties. In contrast, fiberglass readily absorbs water, which can reduce its R-value by 20% Zu 50% while wet, and it takes significantly longer to dry out completely.

Is there a fire resistance difference based on the facing material used?

Ja, the facing material impacts fire safety ratings. Unfaced mineral wool typically achieves a zero flame spread and smoke development rating. Jedoch, applying a combustible facer like kraft paper to fiberglass increases the fire risk, as the paper itself contributes to flame spread and smoke generation.

What are the long-term VOC emissions for these materials?

Both materials are available in low-VOC formulations that meet indoor air quality standards. Modern fiberglass products often use binder-free technologies to eliminate formaldehyde. While rock wool manufacturing involves high-heat processes that release VOCs at the factory, the finished installed product is stable and safe for indoor use.

What is the typical lead time for large custom-sized insulation orders?

Industry standards for custom or large-volume orders typically range from 4 Zu 8 weeks. Manufacturers generally require a 6-week planning horizon to allocate production slots and arrange logistics for non-standard specifications.