Selecting the right insulation for commercial envelopes and industrial equipment often comes down to fire resistance and structural stability. Rock wool insulation distinguishes itself from lighter alternatives by handling operating temperatures above 1260°C while maintaining dimensional rigidity under heavy cladding loads.

This guide covers the essential specifications for integrating stone wool into HVAC, wall assemblies, and process equipment. We evaluate critical performance metrics, including density ranges of 40–150 kg/m³ and compliance with Euroclass A1 non-combustible ratings, to help you select the correct material for load-bearing and acoustic applications.

Lana de Roca vs.. Lana de roca: Technical Differences

Technically, ‘lana de roca‘ y ‘stone wool’ are synonyms describing insulation made primarily from basalt or igneous rock. The substantive difference in the industry is between true stone wool (natural rock) y lana de escoria (blast-furnace slag). Both are high-density materials (40–150 kg/m³) with melting points exceeding 1260°C, offering superior fire resistance and compressive strength compared to standard glass wool.

Terminology and Composition: Basalt vs. Slag

In technical standards, “lana de roca” y “stone wool” function as interchangeable terms for mineral wool produced from natural igneous rock, such as basalt and diabase. The primary manufacturing distinction lies between pure stone wool, which is basalt-based, y lana de escoria, which utilizes iron or copper blast-furnace slag as the main raw material.

Industry bodies like NAIMA and ASTM categorize these materials under the broader “rock and slag wool” definition, acknowledging their similarities in fibrous structure. Sin embargo, specific formulations influence the final product’s color and fiber resilience, distinguishing pure igneous rock products from those heavily reliant on metallurgical slag byproducts.

Densidad, Thermal Conductivity, and Fire Performance

Stone wool typically features a high density range of 40–150 kg/m³, providing rigid dimensional stability compared to lighter glass wool, which generally ranges from 10–50 kg/m³. This density profile supports the material’s ability to resist compression and maintain thickness under cladding loads.

Conductividad térmica (λ-values) for these products generally falls between 0.033–0.045 W/(m·K) when tested to ASTM C518 standards. Beyond thermal control, the material exhibits extreme heat resistance with a melting point of approximately 1260°C, allowing it to achieve Euroclass A1 non-combustible ratings and meet strict ASTM E84 surface burning criteria.

Key B2B Applications (climatización, Paredes, Industrial)

Rock wool serves three primary B2B sectors: HVAC ductwork for thermal and acoustic control, commercial wall assemblies for fire containment and sound dampening, and heavy industrial processing for high-temperature equipment protection. Products range from lightweight duct wraps to high-density industrial boards capable of withstanding extreme heat.

Scope of Application: climatización, Envelope, and Process Equipment

HVAC systems utilize specialized rock wool configurations, including duct wraps, rigid liners, and pipe sections, to maintain thermal consistency and dampen airflow noise within commercial infrastructure. By mitigating thermal bridging and mechanical vibration, these applications ensure energy efficiency while significantly reducing the acoustic footprint of mechanical systems in office complexes and institutional buildings.

Commercial wall assemblies employ semi-rigid stone wool batts to establish critical fire and acoustic barriers within the building envelope. These products are integral to perimeter fire containment systems and cavity insulation, effectively separating floors and preventing flame passage in curtain wall designs while simultaneously reducing sound transmission between tenanted spaces.

Technical Performance Standards and Density Requirements

HVAC insulation products typically feature densities ranging from 35 a 48 kg/m³ to balance weight with acoustic damping performance. Service temperatures for these applications generally cap at 230–250°C, complying with EN 14303 standards for factory-made mineral wool in building equipment. Thermal conductivity benchmarks for standard duct wraps align closely with 0.035 con/(m·K) at 50°C, ensuring consistent energy retention across distribution networks.

Industrial technical insulation requires significantly higher mass to resist mechanical stress and thermal degradation. Manufacturers engineer these boards with densities between 96 y 150 kg/m³, allowing them to withstand continuous operating temperatures up to 750°C. This high density supports structural integrity under the heavy metal cladding often required in processing plants and power generation facilities.

Fire compliance remains a universal priority across all density ranges. Products adhere to Euroclass A1 and ASTM E136 non-combustibility ratings, forming the core of wall assemblies designed to meet 1- to 2-hour fire-resistance criteria. These standards ensure that the insulation contributes no fuel to a fire, maintaining the safety of the building envelope and industrial assets during critical events.

Understanding R-Value and Density for Commercial Projects

Commercial rock wool typically offers an R-value of R-3.8 to R-4.3 per inch, superior to standard fiberglass batts. While density does not linearly increase R-value, higher density (8–12 lb/ft³) is critical for fire resistance, acoustic dampening, and compressive strength in heavy-duty applications like roofing and curtain walls.

| Material Type | Typical R-Value (per Inch) | Primary Commercial Advantage |

|---|---|---|

| Commercial Stone Wool | R-3.8 – R-4.3 | Resistencia al fuego & resistencia a la compresión |

| Standard Fiberglass | R-2.2 – R-2.7 | Cost-effectiveness for interiors |

| Closed-Cell Spray Foam | R-6.0 – R-7.0 | Maximum thermal resistance per inch |

| High-Density Fire Batt (3″) | ~R-4.2 (R-12.6 Total) | Perimeter fire containment |

Sound Dampening Standards (NRC) for Contractors

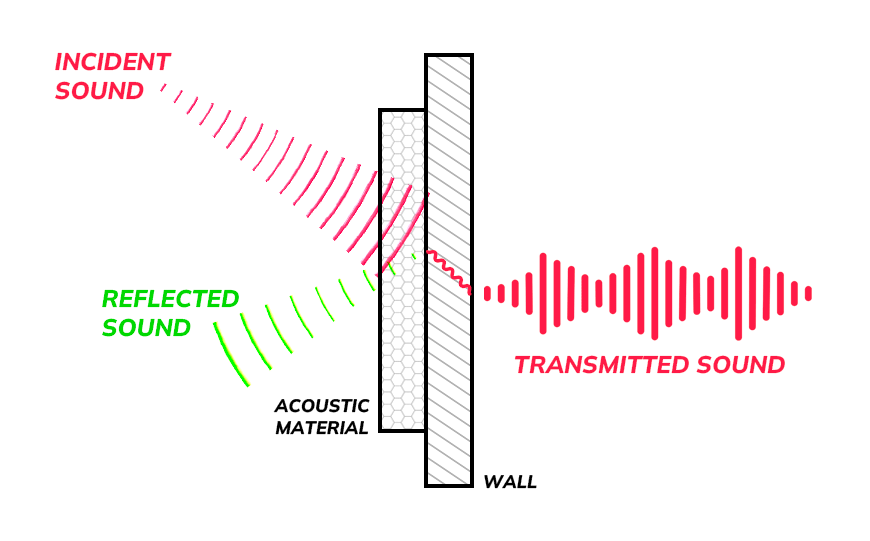

The Noise Reduction Coefficient (NRC) measures a material’s sound absorption capabilities on a scale from 0.00 (reflective) a 1.00 (absorptive). Contractors rely on these ratings, determined via ASTM C423 testing, to control reverberation in commercial spaces. For effective noise reduction in offices and schools, industry standards typically demand materials with an NRC of 0.70 o superior.

Decoding the NRC Scale and ASTM C423 Protocols

NRC quantifies sound absorption by averaging coefficients at four specific speech frequencies: 250 Hz, 500 Hz, 1,000 Hz, y 2,000 Hz. Testing follows the mandatory ASTM C423 protocol to ensure consistent data across different insulation manufacturers. The scale ranges from 0.00, representing perfect reflection like glass, a 1.00 for perfect absorption, though edge diffraction in testing can sometimes yield results slightly above 1.0.

Materials rated NRC 0.80 or higher define the “High-Performance” category for professional acoustic applications. The Sound Absorption Average (SAA) is gradually replacing NRC in updated specifications by measuring 12 frequency bands between 200 Hz and 2,500 Hz, offering higher precision for complex acoustic environments.

Project Specifications: Target Ratings by Application

Commercial projects require specific NRC levels based on the building’s function. Classrooms demand a minimum NRC of 0.75 to reduce reverberation time (RT60) and maintain speech intelligibility. Call centers and open-plan offices require high absorption ranges of NRC 0.85–1.00 to prevent noise spillover, while general circulation areas like lobbies and corridors typically function well with moderate ratings between 0.60 y 0.75.

Contractors must distinguish NRC, which handles internal echo absorption, from Sound Transmission Class (STC), which measures how well a barrier blocks sound from passing through. Installing panels with an NRC below 0.50 usually offers insufficient dampening for commercial environments expecting effective acoustic performance.

The Future of Rock Wool: Sustainability and Recycled Content

Rock wool insulation supports sustainability through high recycled content—often up to 60% using slag and basalt—and is 100% recyclable at the end of its life. Its production adheres to MACT standards and utilizes closed-loop water systems, while recycling stone wool can reduce carbon emissions by nearly 10% compared to virgin material production.

Recycled Content Ratios and Circular Lifecycle

Modern rock wool formulas prioritize the use of secondary raw materials to minimize environmental impact. Manufacturers, such as American Rockwool, incorporate up to 60% recycled content into their products, primarily derived from blast furnace slag and natural basalt rock. This strategy effectively diverts industrial byproducts from landfills and reduces the energy required to mine and process virgin stone.

The material supports a circular economy model because it remains 100% recyclable at the end of its service life. Unlike some insulation materials that degrade over time, rock wool retains its physical properties, allowing manufacturers to remelt old batts into new insulation without a loss in thermal performance or fire resistance. This indefinite reuse cycle significantly lowers the long-term environmental footprint of the building envelope.

Manufacturing Standards and Carbon Emission Reductions

Integrating recycled stone wool into the manufacturing process yields measurable carbon benefits. Data indicates that recycling stone wool into new products reduces carbon emissions by approximately 10% compared to production cycles that rely exclusively on virgin rock. This reduction contributes to lower embodied carbon in construction projects aiming for sustainability certifications.

Installation Best Practices for Large-Scale Projects

Proper installation is critical for maintaining rock wool’s rated R-value of 3.7 a 4.3 por pulgada. NAIMA standards require batts to completely fill cavities without compression, gaps, or voids. For large commercial roofs or attics, contractors often use a multi-layer strategy—placing the first layer parallel to framing and the second perpendicular—to eliminate thermal bridging.

Maximizing Thermal Performance: Cavity Fill and Layering

Achieving the specified thermal performance in commercial wall and ceiling assemblies requires strict adherence to NAIMA’s “Tech Tips” for mineral fiber installation. Batts must completely fill the cavity, fitting snugly against all sides, ends, and contact surfaces without compression. Even minor gaps or voids allow convective air movement that significantly degrades the system’s overall R-value. Installers must cut material to exact dimensions rather than compressing oversized batts into standard stud bays, as maintaining the natural loft of the stone wool is essential for its insulating efficiency.

For large-scale attic projects targeting high thermal resistance codes (p.ej., R-30, R-38, or R-49), a specific multi-layer sequencing strategy prevents thermal loss through framing members. The first layer of batts is installed parallel to the framing, flush with the bottom and top of the chords. A second layer is then installed perpendicular to the framing members. This cross-directional layering effectively covers the structural lumber or steel, mitigating thermal bridging and creating a continuous, high-performance thermal barrier across the entire roof deck.

Exterior Continuous Insulation and Mechanical Fastening

High-density rigid boards, such as Comfortboard 80, are frequently specified as continuous insulation (CI) for commercial building facades to break thermal bridges created by steel studs. Unlike lightweight foam, stone wool boards require robust mechanical fastening. Boards are typically secured through furring strips or specialized cladding supports that penetrate through to the structural substrate. This installation method ensures the insulation remains dimensionally stable under wind loads and provides a flat, rigid base for the subsequent cladding application.

Integrating rigid stone wool into the building envelope requires careful detailing at transitions to maintain air and water tightness. Installers must coordinate the insulation layout with window flashing and water-resistive barriers (WRBs), ensuring that all penetrations are sealed against moisture intrusion. Además, safety protocols on commercial sites must mandate appropriate Personal Protective Equipment (PPE) for crews handling these materials. Standard requirements include long sleeves, guantes, eye protection, and dust masks or respirators to protect against fiber irritation during cutting and installation.

Premium Rock Wool Manufacturing: Fireproof & Energy-Efficient Solutions

Pensamientos finales

Selecting rock wool requires balancing thermal performance with long-term safety and compliance. High-density stone wool delivers superior fire resistance, control acustico, and dimensional stability, making supplier reliability just as critical as product quality.

Project success depends on verified specifications and sourcing from a trusted proveedor de aislamiento de lana de roca. Working with certified rockwool factories and experienced suppliers of rockwool insulation ensures consistent compliance with ASTM and Euroclass standards.

For dependable mineral wool solutions, contact our team at https://chinathermalinsulation.com/ for technical support and tailored quotations.

Preguntas frecuentes

What is the expected service life of rock wool in industrial applications?

Standards generally assign a service life of 50–60 years to stone and rock wool insulation. Field data supports this, showing stable performance without degradation for over 65 years when the material is installed correctly.

How does fiber orientation affect the strength of rock wool boards?

Vertical fiber orientation creates significantly higher compression resistance than horizontal orientation. Boards produced with pendulum methods align fibers vertically, which improves load distribution and bonding strength compared to sedimentation-based horizontal fibers.

Which fire rating is required for load-bearing assemblies?

Load-bearing assemblies must meet the ‘R’ performance criterion. In commercial projects, walls and floors typically require a minimum rating of REI 60 (60 minutes), increasing to REI 90 or REI 120 for high-risk or high-rise structures.

What is the best way to reduce dust when cutting rock wool?

Contractors should use low-speed hand tools, such as knives or handsaws, rather than high-speed power saws. For cleanup, industrial vacuums rated for Dust Class M are recommended over dry sweeping to prevent airborne particles.

Can rock wool be used for Continuous Insulation (CI) systems?

Sí, high-density rock wool boards are engineered specifically for Continuous Insulation (CI) applications. They act as rigid, non-structural sheathing that covers framing members to meet ASHRAE 90.1 energy standards.

How do installers mitigate thermal bridging with rock wool?

Thermal bridging occurs when heat travels through conductive studs or pipes. Installers mitigate this by applying a continuous layer of rock wool insulation over the exterior framing, ensuring no gaps exist at joints or penetrations.