Engineers facing furnace temperatures above 1000°C know that distinguishing between a material’s classification rating and its continuous service limit is vital for preventing lining failure. Ceramic fiber blankets offer a lightweight solution, yet specific chemical compositions determine their stability against thermal shock and shrinkage.

This guide outlines the technical differences between standard 1260°C blankets and Zirconia-stabilized variants capable of withstanding 1430°C. We analyze how needling processes increase tensile strength above 60 KPa and review the impact of density on thermal conductivity, focusing on why 128 kg/m³ remains the optimal balance for most high-heat applications.

What Is a Ceramic Fiber Blanket?

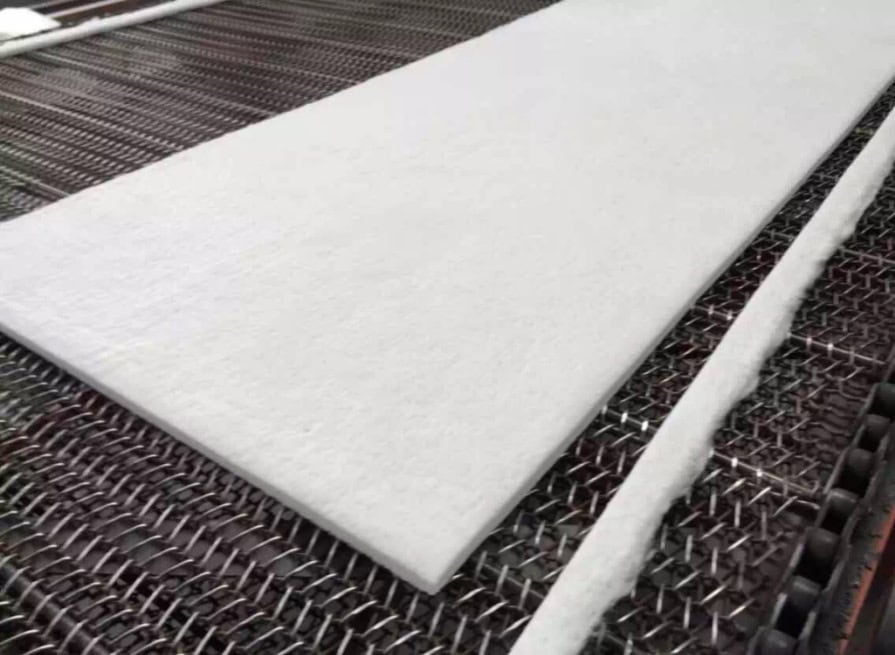

A ceramic fiber blanket is a lightweight, high-temperature refractory insulation material composed of spun alumina-silica fibers. Manufactured through a mechanical needling process that eliminates the need for organic binders, it withstands temperatures between 1260°C (2300°F) and 1430°C (2600°F) while maintaining low thermal conductivity and flexibility.

Composition and Needled Manufacturing Structure

Engineers manufacture ceramic fiber blankets from high-purity alumina-silica fibers, typically containing 47–52% Al₂O₃. These raw materials are melted and spun into long, flexible filaments that form the base matrix of the insulation. Unlike rigid refractories, this fibrous structure traps significant amounts of static air, delivering insulation values up to five times superior to traditional refractory bricks or castables.

The structural integrity of the blanket comes from a double-sided “needling” process. This mechanical method interlocks the fibers in a cross-lapped pattern, ensuring high tensile strength (≥60 KPa) without the use of organic binders. The absence of binders prevents the release of smoke or fumes during initial heating and ensures the material retains its physical properties even in oil-corrosion environments. This construction allows the material to resist thermal shock and chemical attack effectively.

Temperature Classifications and Physical Specifications

Industrial users categorize these blankets based on maximum service temperature. The most common classifications are Standard Grade, rated for 1260°C (2300°F), and Zirconia Grade, rated for 1430°C (2600°F). The Zirconia variants include approximately 15% ZrO₂ to stabilize the fibers at extreme temperatures, preventing excessive shrinkage and crystallization.

Key Features of Ceramic Fiber Blankets for High-Temperature Use

Ceramic fiber blankets offer exceptional thermal insulation with low thermal conductivity (0.06–0.32 W/m·K) and resistance to thermal shock. They feature low heat storage and controlled linear shrinkage, capable of withstanding classification temperatures from 1260°C (Standard) up to 1600°C (PCW) for demanding furnace and kiln applications.

Thermal Stability and Resistance Capabilities

Ceramic fiber blankets maintain insulation efficiency across a broad thermal range. Thermal conductivity remains low, measuring approximately 0.06 W/m·K at 200°C and rising only to about 0.32 W/m·K at 1000°C. This property ensures minimal heat loss even during sustained high-temperature operations. The material handles rapid temperature fluctuations effectively due to its fibrous, interlocking structure. This thermal shock resistance prevents cracking or spalling when furnaces cycle between heating and cooling phases, a critical requirement for batch kilns.

Low heat storage capacity further enhances energy efficiency. Unlike dense refractories that absorb significant energy to reach operating temperature, ceramic fiber blankets heat up and cool down quickly. Chemical stability is another defining characteristic. These blankets resist attack from most acids and alkalis, although hydrofluoric acid and concentrated phosphoric acid remain exceptions. For environments containing corrosive atmospheres, high-purity and Polycrystalline Wool (PCW) grades provide superior resistance compared to standard alumina-silica blends.

Classification Grades and Physical Specifications

Temperature classification grades define the safe operating limits for specific blanket types. Standard grade blankets are classified up to 1260°C and typically contain 43–44% alumina (Al₂O₃). Zirconia grades, which incorporate at least 15% zirconium dioxide (ZrO₂), extend this classification to 1425°C. For the most demanding applications, Polycrystalline Wool (PCW) variants reach classification temperatures of 1600°C with alumina content ranging from 71% para 73%.

Physical stability under heat is measured by linear shrinkage. Standard grades maintain linear shrinkage below 2.5% at 1000°C over 24 hours. PCW grades offer tighter dimensional control, with shrinkage limited to 1.0% or less at 1400°C. Density options typically range from 64 kg/m³ to 160 kg/m³ (4–10 pcf). Higher densities correlate with increased mechanical strength and better resistance to gas flow erosion. Tensile strength requirements, governed by standards such as ASTM C892, ensure the material withstands handling and installation without tearing.

How Ceramic Fiber Blankets Are Manufactured

The manufacturing process begins by melting high-purity alumina and silica in electric furnaces, then spinning the melt into 1–6 µm fibers. These fibers are collected and mechanically needled to form a binder-free mat with high tensile strength. Finalmente, the blanket undergoes heat treatment to minimize shrinkage and is cut to specific densities and sizes.

From Raw Material Melting to Fiber Spinning

Production starts with the precise batching of raw minerals, primarily high-purity alumina (Al₂O₃) and silica (SiO₂). For higher-temperature grades rated above 1260°C, manufacturers introduce zirconia (ZrO₂) or significantly increase alumina content to enhance thermal stability. This mixture melts in electric resistance furnaces at temperatures exceeding the fiber’s final working rating, ensuring a homogenous liquid stream free of impurities that could cause early crystallization or failure in service.

The molten stream is immediately converted into fibers using high-speed multi-roller spinners or high-pressure air blowing. This fiberization stage dictates the fiber geometry, targeting a median diameter between 1 e 6 microns. Advanced process controls strictly limit non-fiberized particles, known as “shot,” to below 15% by weight. Maintaining low shot content is critical, as excess shot reduces the material’s insulation value and increases weight without adding structural integrity.

Needling, Heat Treatment, and Sizing

Once spun, the loose fibers settle onto a moving conveyor belt to form a continuous web. The industry uses a double-sided mechanical needling process to cross-lap and interlock the fibers vertically. This physical entanglement creates a completely binder-free blanket with significant tensile strength, often exceeding 75 kPa. By eliminating organic binders, the blanket maintains its physical structure even when exposed to direct flame, avoiding the smoke and outgassing issues associated with binder burn-off.

The needled mat then passes through a thermal setting furnace. This heat treatment stabilizes the fiber structure and pre-shrinks the material, ensuring that permanent linear shrinkage remains below 2.5% para 3.0% during service at rated temperatures. Finalmente, the continuous blanket is trimmed, slit, and rolled into standard dimensions. Manufacturers control the feed rate and compression during this stage to achieve specific bulk densities, typically ranging from 64 kg/m³ for light insulation to 160 kg/m³ for high-durability linings.

Premium Rock Wool Insulation Solutions

Ceramic Fiber Blanket Types and Density Options

Ceramic fiber blankets are primarily categorized by temperature rating, ranging from Standard (1260°C) to High-Purity and Zirconia grades (up to 1600°C). Density options typically span from 96 kg/m³ to 160 kg/m³, where higher density (por exemplo, 128 kg/m³) offers superior thermal resistance (0.09 W/m·k at 400°C) at the cost of increased weight. Selection depends on balancing heat containment needs with structural load limits.

| Grade Classification | Max Temp Rating | Composition Profile | Typical Application |

|---|---|---|---|

| Standard Grade | 1260°C (2300°F) | Alumina-Silica (Al₂O₃ ≈ 44%) | General kiln linings & backup insulation |

| High-Purity Grade | 1260°C – 1350°C | High Alumina (≥45-52%) | Chemical stability in aggressive environments |

| Zirconia Grade | 1430°C (2600°F) | Al₂O₃-SiO₂ + 15-17% ZrO₂ | High-heat industrial zones & rapid cycling |

| Polycrystalline (PCW) | 1600°C (2912°F) | High Alumina (>70%) | Extreme heat & chemical attack resistance |

Classification by Temperature Grade and Composition

The industrial market classifies ceramic fiber blankets into distinct grades defined by chemical purity and thermal resistance ceilings. Standard Grade blankets, rated for 1260°C, utilize a blend of approximately 45–46% alumina and silica. These are engineered for general applications such as kiln linings and annealing furnaces where continuous operating temperatures remain below 1050°C. For environments requiring greater chemical stability, High-Purity variants increase the alumina content (≥43-52%) and reduce impurities like iron oxide and alkalis, preventing material degradation in aggressive atmospheres.

Applications exceeding 1300°C necessitate advanced material compositions to mitigate shrinkage and fiber crystallization. Zirconia Grade blankets incorporate 15–17% Zirconium dioxide (ZrO2) into the alumina-silica matrix, raising the classification temperature to 1430°C. This addition stabilizes the fiber structure against extreme heat, ensuring minimal shrinkage. At the top of the performance spectrum, Polycrystalline Wool (PCW) variants operate up to 1600°C, leveraging high-alumina content (>70%) to withstand the most severe thermal cycling and chemical attacks found in specialized metallurgy.

Ceramic Fiber Blankets vs. Other High-Temperature Insulation Materials

Ceramic fiber blankets outperform glass wool and lã de rocha in environments exceeding 1000°C, offering service ratings from 1260°C to 1600°C compared to the 600°C–1000°C limits of mineral wools. While significantly lighter (96–128 kg/m³) than dense refractory bricks (~3500 kg/m³), they provide superior thermal conductivity (0.15 W/m·K at 600°C) and chemical stability, making them the standard for high-heat industrial furnace linings.

| Insulation Material | Max Service Temp | Typical Application |

|---|---|---|

| Lã de vidro / Fibra de vidro | ~600°C (1100°F) | AVAC, low-heat piping, commercial boilers |

| Lã de pedra (Mineral) | ~1000°C (1832°F) | Industrial ovens, fire protection, insonorização |

| Manta de fibra cerâmica | 1260°C–1600°C | Furnace linings, fornos, molten metal backup |

| Dense Refractory Brick | >1600°C+ | Load-bearing structures, glass tank flux lines |

Comparison with Mineral Wool and Fiberglass: Temperature Thresholds

The primary distinction between ceramic fiber and mineral wools lies in their thermal decomposition points. Glass wool and standard fiberglass textiles, such as Tempmat, operate effectively up to 600°C–650°C (1200°F). Beyond this threshold, the binders in fiberglass degrade rapidly, and the fibers themselves may soften or devitrify under thermal stress. Rock wool extends this range slightly, offering moderate resistance up to roughly 1000°C, yet it often lacks the structural integrity required for direct flame impingement or the cyclic heating found in metallurgical furnaces.

Ceramic fiber blankets are engineered specifically to cover the 1050°C–1600°C range where mineral wools fail. Standard alumino-silicate grades are rated for continuous use at 1260°C, while high-alumina and zirconia variants handle up to 1430°C. Additionally, while fiberglass mats are frequently limited to 1-inch thickness due to manufacturing constraints, ceramic fiber blankets are produced in thicknesses up to 2 inches (50milímetros), providing superior single-layer insulation for high-heat containment.

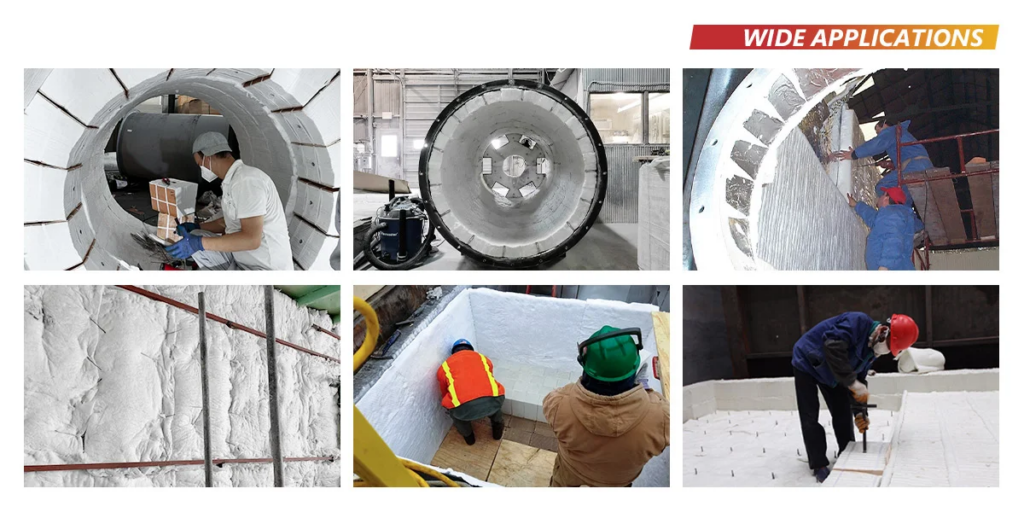

Common Industrial Applications of Ceramic Fiber Blankets

Ceramic fiber blankets are primarily used as thermal linings for furnaces, fornos, and boilers in the steel, glass, and petrochemical industries, handling temperatures between 1050°C and 1450°C. Beyond heat containment, they serve critical roles in passive fire protection, pipe wrapping, and expansion joint sealing for power generation and chemical processing facilities.

Refractory Linings and Heavy Industrial Furnaces

High-temperature processing equipment relies on ceramic fiber blankets for critical heat retention and energy efficiency. In industrial ovens, steam reformers, and boilers, these blankets function as either the hot-face lining exposed directly to heat or as backup insulation behind refractory bricks. Standard density blankets (128 kg/m³) represent the industry norm for these applications, providing structural integrity without adding excessive weight to the furnace shell.

The steel, glass, and chemical processing sectors utilize alumino-silicate fibers to withstand continuous operating temperatures ranging from 1050°C to 1450°C. Low thermal conductivity—approximately 0.21 W/m·K at 816°C—ensures that process temperatures remain stable while fuel consumption decreases. For aggressive environments containing acids or alkalis, operators specify Polycrystalline Wool (PCW) cobertores, which maintain stability up to 1600°C (2912°F) and resist chemical attack better than standard formulations.

Fire Protection and Specialized Thermal Management

Beyond standard furnace linings, ceramic fiber blankets act as essential safety barriers in passive fire protection systems. Specific grades meet UL 723 standards for surface burning characteristics, making them suitable for firestops in building assemblies and industrial enclosures. In the power generation sector, these materials insulate turbines, thermal reactors, and nuclear generators, protecting external components and personnel from extreme internal heat.

The material’s flexibility allows maintenance teams to wrap high-temperature pipes and fabricate gaskets or expansion joints for metal casting equipment. This adaptability is particularly useful for repair and retrofit operations, where technicians use blankets—available in rolls up to 7.2 meters long—to quickly patch degraded insulation or cover damaged refractory brick, minimizing downtime during unplanned outages.

How to Choose the Right Ceramic Fiber Blanket for Your Project

Selection begins by matching the continuous operating temperature to the correct grade (Standard 1100°C, High Purity 1260°C, or Zirconia 1430°C). Engineers must then determine the optimal density (typically 96–128 kg/m³ for furnace linings) and calculate the necessary thickness to meet thermal resistance goals while ensuring chemical compatibility with process gases.

| Blanket Grade | Classification Temp | Recommended Use Limit | Key Chemical Characteristic |

|---|---|---|---|

| Standard (ST) | 1260°C (2300°F) | 1050°C (1922°F) | Al₂O₃ ≥ 43–44% |

| High Purity (HP) | 1260°C (2300°F) | 1100°C (2012°F) | Low Iron/Alkali Content |

| Zirconia (HZ) | 1430°C (2600°F) | 1350°C (2462°F) | ZrO₂ ≥ 15% (Stabilizer) |

| Polycrystalline (PCW) | 1600°C (2912°F) | 1500°C (2732°F) | Al₂O₃ 72% + SiO₂ 28% |

Selecting the Optimal Temperature Grade and Chemical Composition

Engineers must distinguish between the classification temperature and the continuous working temperature when specifying materials. The classification temperature represents the extreme limit where material shrinkage hits a standard threshold (typically 3–4% over 24 hours), not the safe temperature for long-term operation. For continuous service, select a grade at least 150°C above the expected furnace environment. Standard (ST) grades suffice for general backup insulation up to 1050°C, while High Purity (HP) grades offer better stability for direct furnace linings up to 1100°C due to reduced iron and alkali impurities.

Determining Density, Grossura, and Layering Requirements

Density directly impacts mechanical strength and thermal conductivity. For exposed furnace linings where high gas velocities or mechanical vibration occur, specify a density of 128 kg/m³ (8 lbs/ft³) ou superior. This density prevents fiber erosion and minimizes linear shrinkage. Conversely, protected back-up layers shielded by hard refractories operate effectively with lower densities like 64 kg/m³ or 96 kg/m³, reducing overall material weight and cost without compromising the system’s thermal efficiency.

OEM and Customization Options for Ceramic Fiber Blankets

OEM services allow manufacturers to tailor ceramic fiber blankets by temperature grade (Standard 1260°C vs. Zirconia 1430°C), densidade (64–128 kg/m³), and physical dimensions, including custom strips and shapes. Suppliers also support private labeling, custom packaging, and specialized formulations like Bio-Soluble or Wet Wool for specific application needs.

Tailoring Specifications: Dimensões, Densidade, and Temperature Grades

Engineers can specify ceramic fiber blankets based on precise thermal and physical requirements rather than relying solely on off-the-shelf inventory. Temperature customization typically distinguishes between Standard Commercial grades (approximately 1260°C / 2300°F) and Zirconia-stabilized grades (1430°C / 2600°F). The Zirconia variants introduce ZrO₂ to the alumina-silica matrix, significantly reducing linear shrinkage and maintaining structural integrity in extreme heat environments where standard blankets might degrade or embrittle.

Branding, Packaging, and Supply Chain Integration

For distributors and large-scale equipment manufacturers, OEM services support full private labeling. This includes custom-printed logos on cartons, bags, and technical documentation, ensuring brand consistency across the product line. Manufacturers can also adapt packaging for logistics efficiency, offering reinforced wooden pallets, weather-resistant wrapping, or specific unit-of-measure rolls to streamline warehouse operations.

Considerações Finais

Ceramic fiber blankets fundamentally change how heavy industries manage thermal energy by reducing structural loads and improving insulation efficiency. For companies sourcing in volume de fibra cerâmica, working with reliable ceramic fiber suppliers ensures consistent quality, stable supply, and long-term performance in high-temperature environments.

Selecting the correct fiber grade and density is essential for durability and energy savings. If you’re seeking trusted ceramic fiber suppliers for standard or customized solutions, visit https://chinathermalinsulation.com/ to explore our products or request a tailored quotation today.